In aquaculture, feed quality directly affects your results. It's not just about the formula-the machine you use matters too. The right equipment influences whether feed floats or sinks, how well nutrients are preserved, and how your fish respond. So, how do you choose? Here's a quick look at the two main types of fish feed machines to help you decide.

Pellet Mill: A Budget-Friendly Choice

For everyday feed production, pellet mills remain a popular option, especially for making sinking fish food. With a simple structure and stable operation, they're well-suited for small to mid-sized farms.

How It Works

Feed Pellet mill compress powdered ingredients into cylindrical pellets using pressure between a roller and a die. The process is straightforward and easy to operate.

Pellet Mill Advantages

- Lower cost: Pellet mills require less investment and consume less energy than extruders-ideal for farms with limited budgets.

- Versatile: Suitable for common fish species like carp, tilapia, and crucian.

- Better nutrient retention: The lower processing temperature helps preserve heat-sensitive nutrients such as vitamins.

Things to Keep in Mind

Pellet mills typically produce sinking feed with high density. If you need floating fish food, additives or special treatment may be required. Also, pellet feed can break easily during transport and stays stable in water for about 2–4 hours-less than extruded feed.

For Floating Feed, Extruder Wins

If you need floating or slow-sinking pellets, a pellet mill alone may not do the job. In this case, an extruder is the better option. Using high temperature and pressure, it not only controls pellet density but also improves feed palatability and nutrient absorption.

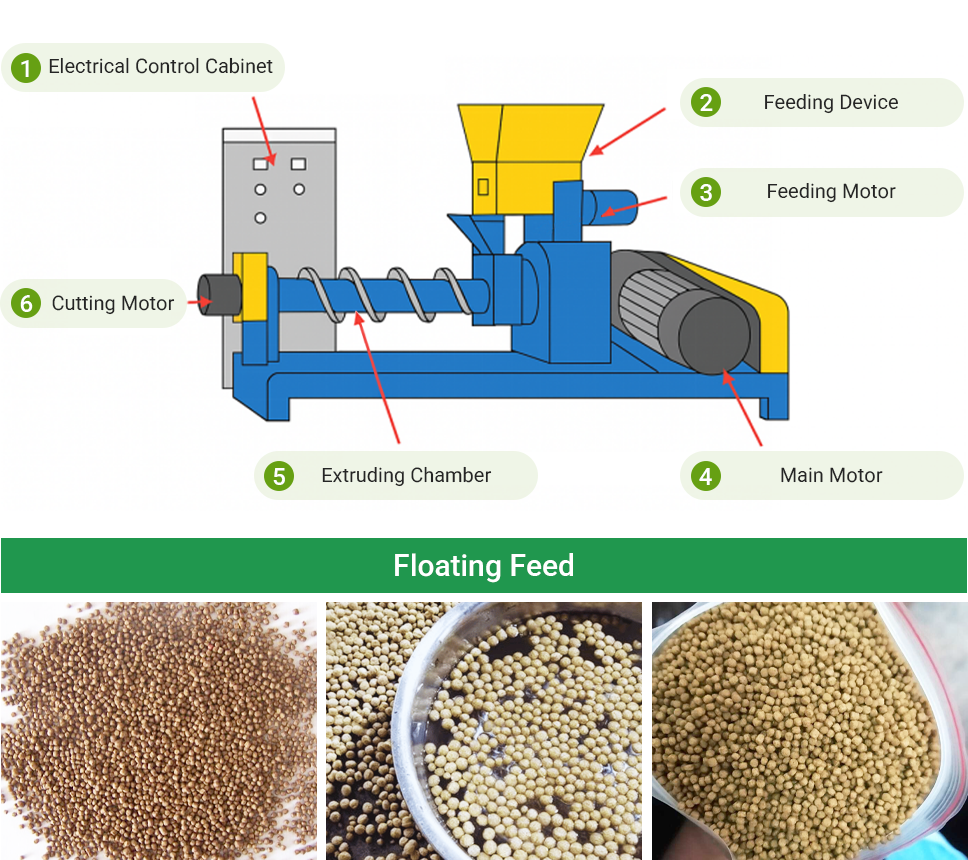

How It Works

Think of it as a mix between a pressure cooker and popcorn. Ingredients are pushed forward by a screw inside a heated, pressurized chamber. Water turns to steam but can't escape. Once the feed exits through a small die opening, the sudden drop in pressure causes it to puff and expand-creating light, porous pellets.

Key Benefits

The biggest advantage of an extruder is its versatility.

It can produce both floating and slow-sinking feed, making it ideal for shrimp, ornamental fish, and other species with special feeding habits. The high temperature and pressure also help gelatinize starch, improving digestibility and nutrient absorption. This means less waste and better water quality. Plus, the extrusion process kills harmful pathogens, making the feed safer and helping reduce the risk of disease.

What to Watch Out For

- Higher cost: Extruders are more expensive than feed pellet machines, both in purchase price and energy use.

- Nutrient loss: High heat can reduce certain heat-sensitive vitamins (Stability of Vitamins during Extrusion) , so post-extrusion coating is often needed to restore them.

Key Comparison Factors

Now that you understand how each machine works, let's break down their main differences to help you decide which one fits your needs best:

| Factor | Pellet Mill | Extruder Machine |

| Cost | Lower | Higher |

| Output | Generally higher | Moderate, depending on settings |

| Energy Use | Low | High |

| Stability | Fairly stable but dissolves faster in water | Excellent & less nutrient loss |

| Palatability | Hard texture, less appealing | Soft, porous, easier for fish to eat |

| Water Quality | Sinking feed may break down and pollute | Floating feed is easy to remove, less impact |

| Fish Types | Common freshwater species | High-value species |

By now, you probably have a clearer idea of how the two machines compare. But before making your final decision, there are still a few key factors to consider-these will determine which machine brings the best return for your operation.

Still Not Sure? Here's How to Decide

Now that you've seen the strengths and limitations of both machines, let's match them to your actual needs-based on your farming goals, scale, and feed formulation.

Farming Goals & Feed Quality

If your main goal is cost-effective farming-focusing on output and raising common freshwater fish with basic feed needs-a pellet mill is a more practical and affordable choice. It covers essential nutrition while keeping both startup and running costs low.

But if you're raising high-value species like shrimp, grouper, or ornamental fish-and care more about feed digestibility, water quality, and biosecurity-then an extruder is the smarter investment. It helps improve feed performance and overall farming quality.

Your Farm Size & Budget

Small farms or individual users

For those new to feed processing or working with a tight budget, pellet mills are ideal. They're affordable, compact, and easy to run-perfect for making your own feed on a small scale.

Large-scale producers

For commercial farms aiming for efficiency and consistency, investing in a full extrusion line makes strategic sense. While the upfront cost is higher, the gains in feed quality, automation, and market competitiveness can deliver long-term returns.

Your Feed Formula

High-starch formulas

An extruder is the better choice here. It fully gelatinizes starch under high temperature and pressure, improving digestion and nutrient absorption for fish and shrimp.

High-protein formulas

A fish feed pellet machine processes at lower temperatures, helping preserve the natural structure and quality of proteins. While extruders can still handle high-protein diets, heat may degrade some sensitive nutrients-requiring post-processing like coating to restore them.

Quick Equipment Selection Guide

| Selection Criteria | Recommended Machine |

| Making sinking feed | Pellet Mill |

| Making floating feed | Extruder |

| Limited budget | Pellet Mill or Small Extruder |

| Targeting high-value returns | Extruder |

| Outdoor farming | Extruder |

| Pond fish food | Extruder |

| Small-scale farm | Pellet Mill |

| Large-scale production | Full Extrusion Line |

| High-starch feed | Extruder |

| High-protein food for fish | Pellet Mill |

| High output required | Pellet Mill |

| Common freshwater species (e.g. grass, bighead, crucian carp) | Pellet Mill |

| Carnivorous or high-value species (e.g. tilapia, catfish, shrimp) | Extruder |

Both pellet mills and extruders have their strengths. Pellet mills are cost-effective and widely used by small to mid-sized farms. Extruders offer better digestibility, higher functionality, and feed safety-ideal for high-value aquaculture. The best choice depends on your specific needs.

We offer reliable fish feed processing equipment for all types of operations. Contact us to learn more or request a custom solution.