Modern bioenergy is accounting for a growing share across multiple industries. Solid biomass is gaining particularly strong traction in industrial applications, especially power generation and heating. It's steadily displacing fossil fuels while showing significant growth potential.

Biomass pellet making machines are essential for transforming raw materials like straw, sawdust, and bark into dense, energy-packed pellets. These versatile pellets offer easy storage and efficient combustion, making them ideal for residential heating, industrial applications, and biomass power plants. It's an eco-friendly solution that saves you money too.

How does a biomass pellet machine operate?

KAWISE biomass pellet maker feature a vertical ring die design, specially designed to compress lightweight, loose, and hard-to-form raw materials. The material naturally drops into the pelletizing chamber due to gravity. As the rotating roller applies high pressure on the stationary ring die, the material is pressed into the die holes.

The heat generated from this high-pressure friction softens the lignin, which then binds the fibers together. This process results in the formation of high-density, uniformly shaped biomass pellets.

Factors Affecting Biomass Pellet Formation

To achieve continuous and stable high-quality pellet production, it is essential to pay attention to the following factors, in addition to the equipment's structural design.

- Choosing the Right Compression Ratio: This is the ratio of compression distance to die hole diameter. Materials with lower bulk density need a higher compression ratio, while those with higher bulk density require a lower ratio.

- Moisture Content: The moisture content should be kept below 20% to allow lignin to release effectively, aiding in better pellet formation.

- Roller-Die Gap: The gap should be set between 0.1-0.3 mm to ensure even material distribution and improve pellet quality.

- Impurities: Impurities like sand and stones can reduce pellet quality and damage equipment. Excessive additives may also affect pellet strength and equipment operation.

Core Advantages of Vertical Structure for Biomass Pellet Production

Vertical pellet machines offer several advantages over horizontal ones:

- Higher Cost-Effectiveness: Vertical pellet machines are more cost-effective due to their compact design. They offer easier operation and lower maintenance, reducing both purchase and operational costs.

- Smaller Footprint: The vertical die and gravity-fed material flow save space, making the structure more compact.

- More Efficient Transmission: With the motor vertically installed and aligned with the main shaft, the power transmission is more direct and precise. This improves the overall mechanical efficiency and strength of the machine.

- Easier Maintenance: Key components like the motor, die, and rollers are centrally located for easy inspection. This reduces downtime and labor costs.

- Material Handling: Vertical pellet machines are ideal for lightweight, fiber-rich materials like straw and sawdust, ensuring smoother pellet formation. Horizontal mills are better for compressing high-density feed.

- Higher Pellet Integrity: Vertical mills, with their discharge disc, provide smoother pellet release. This reduces the risk of breakage compared to horizontal mills.

KAWISE Vertical Biomass Pellet machines for Sale

| Model | Power (kw) | Capacity(t/h) | Weight (t) | Pellet Size (mm) | Die Diameter (mm) |

| KH-450 | 75 | 0.7-1 | 4 | 4-12 | 450 |

| KH-560 | 90 | 1-1.5 | 6.5 | 4-12 | 560 |

| KH-680 | 160 | 1.5-2.5 | 8.5 | 4-12 | 680 |

| KH-850 | 220 | 2-3.5 | 12.6 | 4-12 | 850 |

| KH-880 | 315 | 3.5-4.5 | 14.5 | 4-12 | 880 |

Please note: If you have other production requirements, please contact us directly, and we can quickly provide a free quote!

Advantages of KAWISE Biomass Pellet Mills

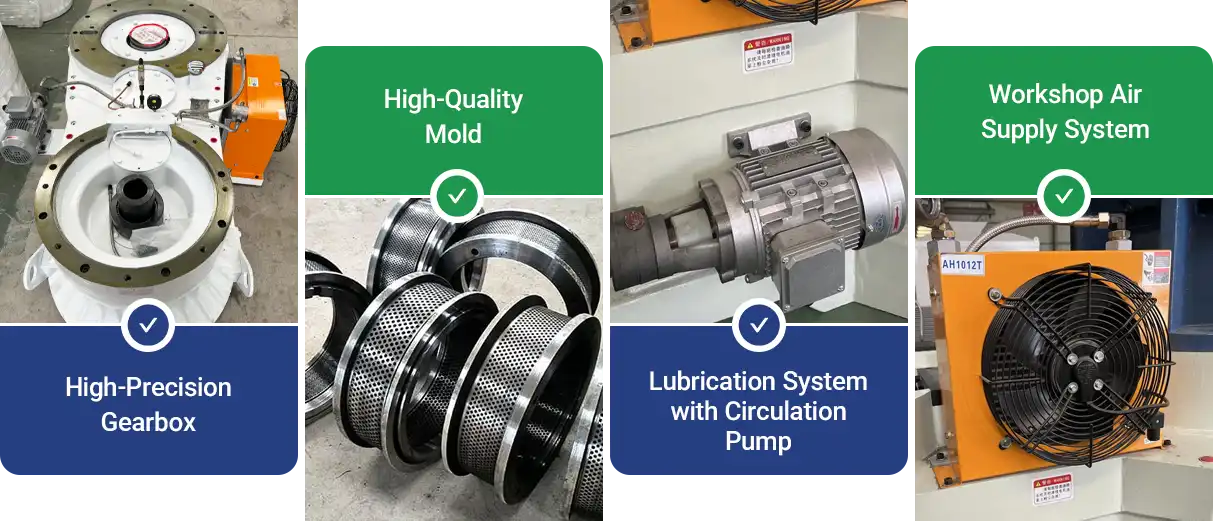

- The gearbox uses a new generation of high-precision gears and an automatic lubrication pump system, ensuring stable operation.

- The die holes are symmetrically arranged around the output shaft. This improves power output and stability, ensuring consistent pellet quality.

- The gearbox features a circulating lubrication pump system, controlled by the roller, with timed oil injection. The oil pump motor automatically circulates lubrication, ensuring continuous lubrication of the main shaft and bearings for safe operation.

- An air supply system is installed on the side of the working chamber. It allows for free control of the working time, ensuring optimal operation and improved efficiency.

- The frequency-controlled vertical feeding system ensures even feeding and facilitates better heat dissipation.

- The optimized vibration reduction system reduces noise during operation.

- Key components are made from high-wear-resistant alloy steel and are precision-machined and heat-treated. This improves durability and wear resistance, significantly reducing long-term maintenance costs.

Buying Vertical Ring Die Pellet machine: Investing in Biomass Pellet Plants

Choosing the right equipment is crucial when investing in a biomass pellet plant. Our vertical ring die pellet machines offer a production capacity ranging from 0.7 to 4.5 t/h. Even for large-scale plants, usually only two or more of these machines are required. For small plants, using a smaller ring die pellet machine is more than sufficient.

KAWISE is a professional pellet machine manufacturer in China, offering factory-priced vertical ring die pellet machines and supporting equipment. We have successfully implemented biomass pellet projects in countries such as Indonesia, Vietnam, Zambia, Canada, Russia, and Romania. This has helped us accumulate rich international experience and provide professional support.

Now is the perfect time to invest in and produce efficient biomass fuel pellets! Choose KAWISE biomass pellet press and join us in moving towards a future of green energy. Contact us today to start your biomass energy journey!