Wood pellets are a clean, renewable fuel used in boilers, heaters, and power plants. They burn hot, store easily, and produce less emissions, making them a better alternative to coal. This 1.5–2 TPH pellet line is perfect for small and medium factories. It's compact, efficient, and lowers production costs.

System Highlights

- Output: 1–1.5 tons/hour continuous biomass pellets production

- Pellet Specs: Diameter 4–12mm; adjustable length & density

- Raw Materials: Sawdust, bamboo shavings, straw, rice husk, palm shells, nutshells, mushroom residue, etc.

- Application Scenario:

Core Equipment and Process Flow

Production Process Overview

Key Equipment (Standard Configuration)

This is a typical biomass pellet production line setup. You can expand or simplify it according to your actual requirements.

Crushing Section

| Equipment | Power(kW) | Description |

| Wood Crusher | 75 | Model:1000. Crush large raw materials into particles |

| Grinder (Optional) | 37 | 1 Refines crushed material into fine powder 2 Improves pellet density and combustion |

| Belt Conveyor | 3 | Transfers material from crusher |

| Cyclone Discharger | 1.5 | Collecting material helps reduce dust |

| Dust Collector | 3 | Captures fine dust after crushing |

| Blower | 5.5 | Moves material via air flow |

| Control Panel | 0.5 | Controls crushing equipment |

Drying Section

| Equipment | Power(kW) | Description |

| Sawdust Dryer | 15 | 1 1200x12000. 2 Reduces moisture to 12-15% for pelletizing |

| Hopper | 0.5 | Temporarily stores material |

| Feeder | 1.5 | Feeds material evenly into dryer |

| Induced Draft Fan | 7.5 | Boosts hot air flow |

| Cyclone Discharger | 1.5 | Collects and discharges dried material |

| Belt Conveyor | 3 | Transfers dry material to pellet section |

Pelletizing Section

| Equipment | Power(kW) | Description |

| Ring Die Pellet Mill | 110 | 1Model:560 2Compresses dry powder into solid fuel pellets |

| Lubrication Station | 0.37 | Automatic oiling system |

| Dust Collector | 3 | Removes dust, improves pellet quality |

| Screw Conveyor | 3 | Ensure smooth material transfer |

| Control Panel | 0.5 | Controls pelletizing operation |

Cooling (Optional)

| Equipment | Power(kW) | Description |

| Z-type Conveyor | 4 | Transfers pellets to cooling bin (500*8000 mm) |

| Cooling Bin | 1.5 | Customizable storage based on layout |

Screening (Optional)

| Equipment | Power(kW) | Description |

| Vibrating Sieve | 2 | Separates fine powder from qualified pellets |

Packing (Optional)

| Equipment | Power(kW) | Description |

| Auto Packing Machine | 3 | Weighs, packs, and seals finished pellets |

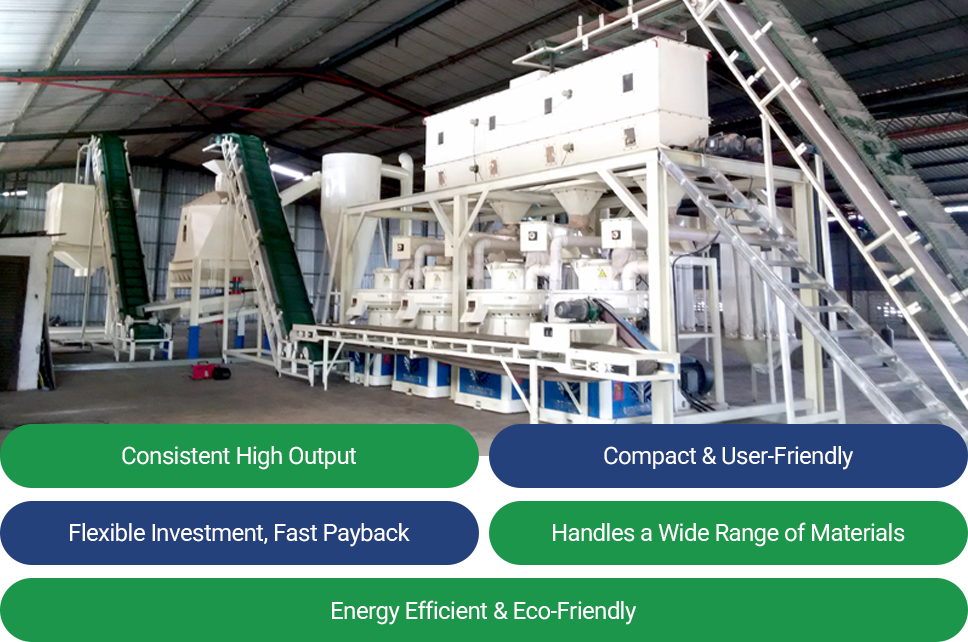

5 Reasons This Line Stands Out

1. Consistent High Output

560 model sawdust pellets mill with 110kW motor delivers up to 1.5 TPH, low failure rate, high durability-ideal for continuous operatio

2. Compact & User-Friendly

Integrated line from crushing to packaging. Tight layout, centralized control system-easy to operate with just 1–2 people.

3. Flexible Investment, Fast Payback

Affordable startup investment, scalable design. Quick setup and short ROI cycle

4. Handles a Wide Range of Materials

Processes wood waste, straw, coffee grounds, and more. Custom dies available to match material types (high oil, moisture, etc.)

5. Energy Efficient & Eco-Friendly

Dust collection and auto-lubrication reduce wear and emissions. Low 213 kW power consumption keeps operating costs in check.

Project Cost and Profit Estimate (Reference Data)

| Daily Output | 16–24 tons (16 hrs/day) |

| Annual Output | 7,200+ tons (300 days) |

| Market Price | $ 200–$ 400/ton (varies by region/material) |

| Total Power | 257–285 kW |

| Electricity Cost | $ 460–$ 1135/month (based on $0.0815–$0.1915/kWh) |

| Estimated Cost | $52,000 – $61,000 |

| Payback Period | Around 1 month, with long-term sustainable profit growth. |

Note: Estimate based on electricity only. Actual returns may vary with labor, raw materials, maintenance, or other variable expenses.

Customer Stories

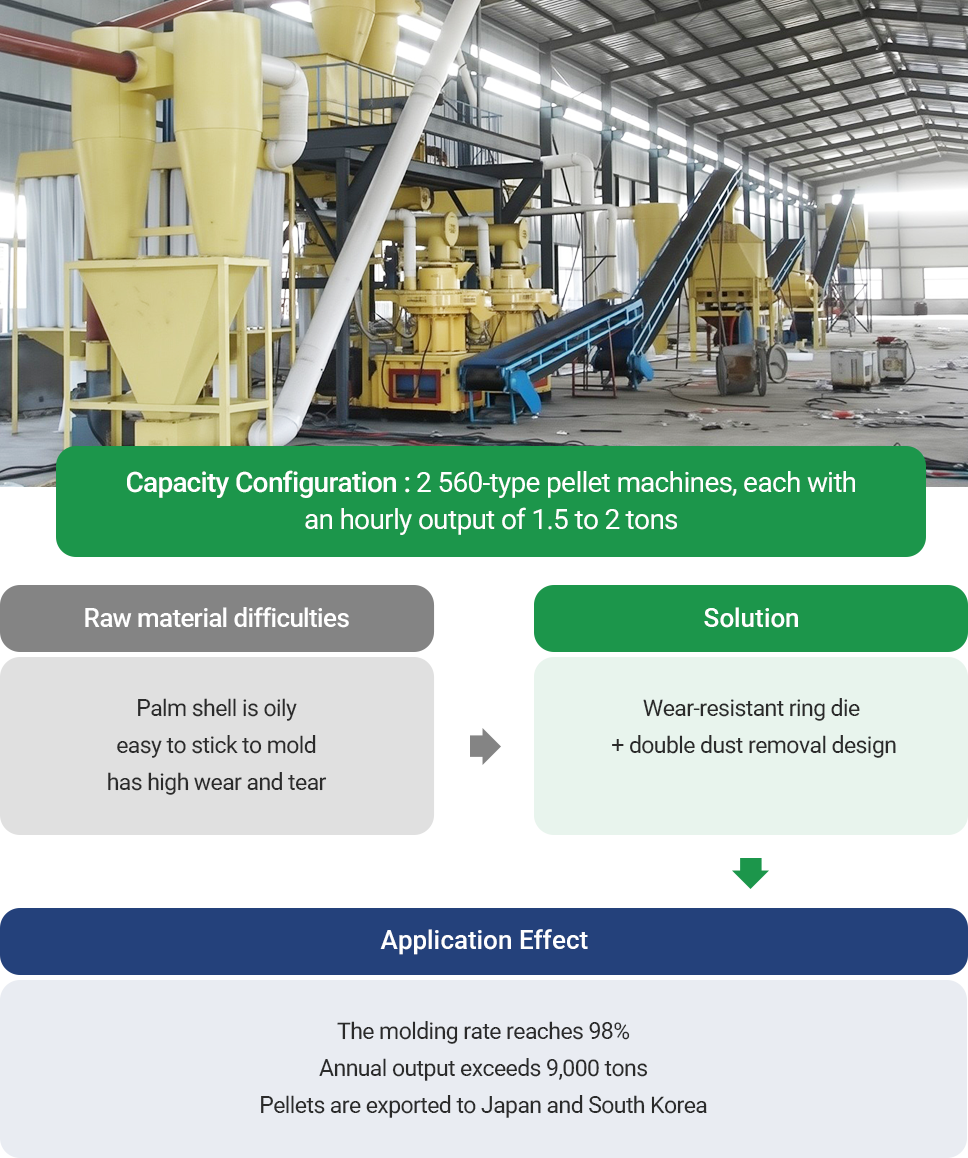

Indonesia – Palm Shell Pellet Export

A Sumatran project uses palm shell waste to produce export-grade biomass fuel pellets for Japanese and Korean energy markets.

Customer Feedback

"We looked at a few different suppliers and ended up going with their pellet machine. It's solid and works well with our palm shell, even though the material's fibrous and mixed. So far, it's been running smoothly, the pellets look great, and our clients are happy. It's a hassle-free partnership, and we look forward to long-term cooperation."

Colombia – Coffee Waste Energy System

A coffee processor in Colombia uses the system to convert coffee grounds and sawdust into biomass wood pellets for self-sustained fuel.

Customer Feedback

"We needed a system for high-moisture raw materials, and this equipment has been perfect. It runs smoothly with almost no issues. The wood fuel pellets burn steadily, and the energy use is low, requiring minimal maintenance. It's efficient and hassle-free."

Kawise – Your Reliable Partner in Biomass Solutions

Whether you're starting fresh or upgrading, this 1.5 TPH biomass wood pellets system is a smart choice for high efficiency and long-term returns.

Planning to start a project? Keep in mind:

- Know your raw materials and moisture content for optimal process design.

- Set clear output goals and factory layout with our detailed plans.

- Estimate budget and timeline-let us help with ROI and investment planning.

Need tailored advice?

Contact us for personalized consultations, custom solutions, and pricing details.