Small pellet machines are the perfect solution for small to medium-scale users in farming, agriculture, and energy industries. Our small pellet machines are becoming more popular because of their efficient design and flexibility. They can easily meet the growing demand for raw material processing, feed, and biomass.

Why Pelletizing Your Materials?

Common production issues you may face:

- Bulky raw materials occupy space and cost more to transport

- Loose materials easily spill, difficult to measure and feed

- Uneven feed nutrition reduces animal intake and growth

- Organic waste piles up, smells bad, hard to manage

- Fuel burns poorly, wasting energy

Pelletizing solves these problems:

- Higher density: Compressed pellets save storage and transport space, cutting costs

- Better flow: Pellets feed smoothly and are easy to measure

- Better feed quality: Balanced nutrition, taste appeal, boosts animal growth

- Odor-free organic fertilizer: Easy to store, eco-friendly, waste recycled

- Efficient combustion: Uniform, low-moisture biomass pellets burn cleaner and hotter

Application & Material Guide

| Purpose | Industry | Recommended Materials | Pellet Size |

| Feed | Aquaculture & Poultry Feed | Rice husk, straw, peanut shells, corn stalks, fish meal | 2.5-4 mm |

| Biomass Fuel | Heating & Power Gen | Sawdust, wood shavings, straw, leaves | 4-5mm |

| Organic Fertilizer | Agriculture | Chicken, pig, cow manure, rice husks, bagasse | 5-8mm |

Tip: Pre-crush and dry materials before pelletizing for better quality.

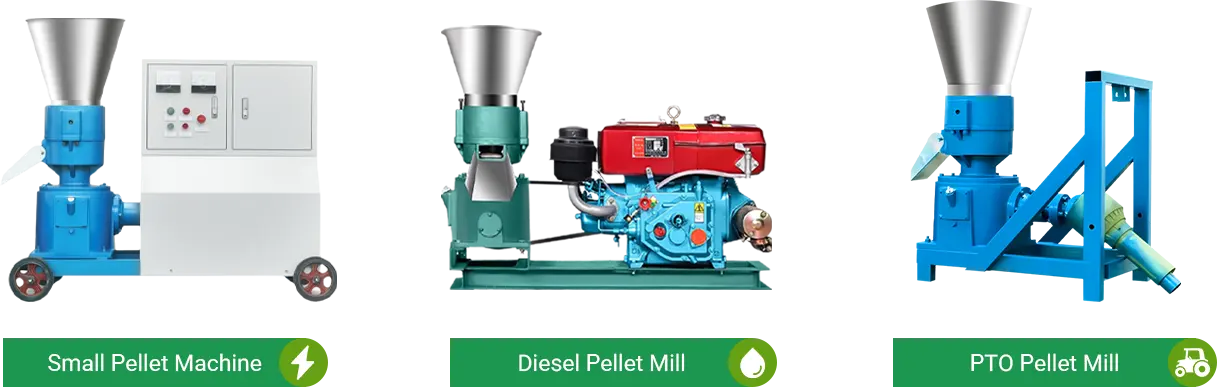

Multiple Power Options for Different Needs

| Drive Type | Suitable Scenarios |

| Electric | Areas with stable power supply; indoor production |

| Diesel | Power-scarce areas; outdoor or mobile operation |

| PTO (Tractor) | Farm users, especially those with existing tractors |

You can choose the right power-driven equipment according to your actual needs.

Easy Operation

- Mix raw materials evenly.

- Slowly feed crushed, mixed materials into the hopper-avoid overloading.

- Machine compresses materials into pellets.

- Cool and store the finished pellets.

Usage Tips:

- Before first use, run fine powder (cornmeal/rice bran) mixed with waste oil (10:1 ratio) for 10-15 minutes to smooth die holes.

- Finer material = better pellet forming.

- Moisture balance is key-too wet clogs die, too dry makes brittle pellets.

- Feed evenly to prevent machine blockage and extend lifespan.

Standard Model Parameters

| Model | Power(KW) | Capacity (KG/H) | Roller |

| KD-125 | 4.5 | 60-100 | 2 |

| KD-150 | 4.5 | 80-150 | 2 |

| KD-160 | 5.5 | 130-200 | 3 |

| KD-180 | 5.5 | 150-220 | 4 |

| KD-210 2R | 7.5 | 200-250 | 2 |

| KD-210 3R | 7.5 | 200-300 | 3 |

| KD-230 | 11 | 250-400 | 3 |

| KD-260 3R | 15 | 300-450 | 3 |

| KD-260 4R | 15 | 300-500 | 4 |

| KD-300 | 22 | 500-700 | 4 |

| KD-400 | 37 | 900-1200 | 4 |

Note: Standard and upgraded versions available. Same performance.

Upgraded version features sealed motors for better durability, standard version offers higher cost-effectiveness.

Why Choose Kawise Small Pellet Machine?

- Compact size: Easy to place, ideal for limited spaces

- Versatile: Change die to adjust pellet size

- Factory direct: Save cost with competitive prices

- Portable design: Built-in wheels for flexible movement

- Durable materials: Alloy steel die & rollers, wear-resistant

- Large feed inlet: Smooth feeding, dense pellets, no clogging

- Eco-friendly: Low noise, low energy consumption

- Continuous operation: Strong anti-fatigue, supports mass production

- Complete accessories & after-sales service

Kawise Small Pellet Machine-your complete solution for efficient, reliable pellet production!

Contact us today for a personalized quote and technical support.