Poultry farming in Tanzania is growing fast. In 2023–2024, the country produced and distributed over 95 million chicks, a 13.9% increase from the previous year. This growth has also brought in valuable foreign exchange.

The government aims to achieve a surplus in poultry meat production by 2026–2027 and strengthen Tanzania's position in regional export markets. The industry clearly has strong potential.

However, feed quality and high production costs remain key challenges.

Poultry Farming in Tanzania

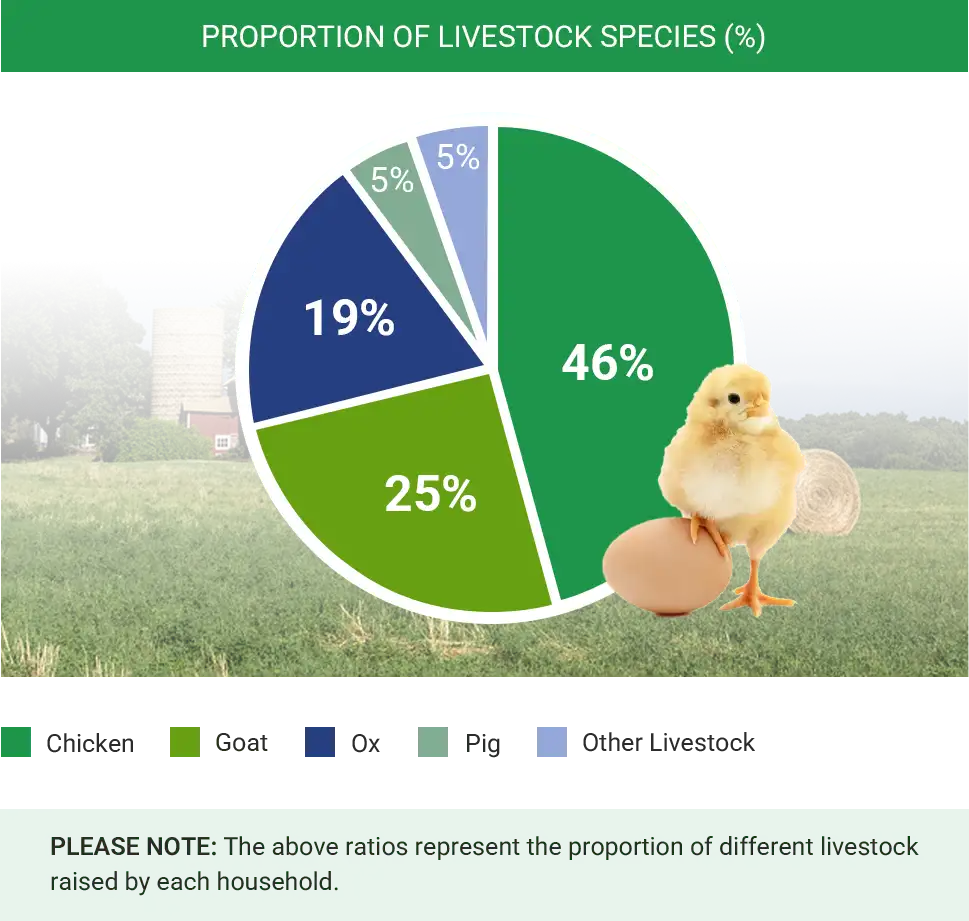

Tanzania is one of the most active poultry-producing countries in East Africa. Around 4.6 million households raise poultry, accounting for about 50% of the population.

Poultry Production Systems in Tanzania

Tanzania currently has about 72 million chickens. Commercial poultry-mainly layers and broilers-along with local breeds, form the core of the country's poultry sector. There are three main farming systems:

Traditional free-range (low input, low output): This is the most common system. It has low production efficiency and mainly serves rural markets.

Improved farming (medium input, medium output): This system combines traditional and modern methods. It usually involves improved local or tropical breeds. Both productivity and management fall between the traditional and commercial models.

Commercial farming (high input, high output): This is the fastest-growing system. It's mainly found in urban and peri-urban areas and is led by small to medium-sized farms. It has strong demand for quality feed and plays a key role in driving industry growth.

Poultry Feed Supply in Tanzania

Tanzania's poultry sector requires around 2.5 million metric tons of feed each year. However, local production meets only about 30% of that demand. This shows a significant supply gap.

Raw Material Supply: Tanzania's production of key feed ingredients-such as soybeans and maize-is limited. Although the country needs about 400,000 tons of soybeans each year, local production can only meet around 20% of that demand. The rest must be imported. This has led to a serious shortage of raw materials, creating a major bottleneck in feed production.

Limited Processing Capacity: Due to limited raw materials and high operating costs, many feed mills are running at less than 50% capacity. While the theoretical capacity for processing soybean meal is sufficient, the lack of extrusion equipment keeps actual utilization low. Feed quality issues are also a growing concern.

High Operating Costs and Logistics Issues: Feed production and transport in Tanzania face high costs, especially for imported raw materials and domestic logistics. Poor transport conditions further limit the expansion of feed mills and reduce the efficiency of raw material use.

There is a clear market gap in Tanzania's poultry feed industry, which presents a strong opportunity for development.

Enter Tanzania's Poultry Feed Mill with a Pellet Machine

A feed pellet mill, one of the key pieces of equipment in feed processing, can compress materials like grass, straw, corn, and soybeans into small pellets. A feed pellet machine offers:

Lower Production Costs

An animal feed pelletizer can process a wide range of raw materials. You can use locally available crops in Tanzania-such as cassava, corn, and sorghum-instead of relying heavily on imported ingredients. This helps reduce the cost of raw material procurement.

The machine also presses raw materials efficiently, minimizing waste and maximizing the use and output of limited resources.

In addition, pellet feed has good flow properties, making it well-suited for use with automated feeding systems. This reduces labor costs and improves overall farming efficiency.

More Efficient Storage and Transport

Pellet feed is compact and dense, which helps save storage space and reduce transport costs compared to traditional feed.

It also flows much better than powdered feed, especially those that contain molasses, high fat, or urea. These powdered types tend to clump during storage and transport, while pellets rarely have that issue.

Higher Feed Efficiency

During the pelleting process, feed is pressed and gently heated, which improves its physical properties, palatability, and digestibility.

When feeding poultry and pigs, pellet feed can increase feed conversion rates by 10% to 12% compared to powdered feed.

For fattening pigs, pellet feed can boost daily weight gain by 4% and reduce the feed-to-meat ratio by about 6%. When used for broilers, it can lower the feed-to-meat ratio by 3% to 10%.

More Balanced Nutrition

You can customize feed formulas based on your farming needs, using different raw materials to ensure balanced nutrition. This helps meet the dietary requirements of animals at different growth stages.

Broader Applicability

By changing the mold, a feed pellet mill can produce pellets of various sizes suitable for different types of livestock and poultry. This flexibility offers a high return on investment.

More Environmentally Friendly

A feed pellet machine can turn agricultural waste-like crop straw and rice husks-into usable feed, reducing pollution from open burning and supporting resource reuse. Pellet feed also produces far less dust than traditional powdered feed, helping improve air quality in both production and farming environments.

Tanzania Feed Processing: 3 Business Models

If you're planning to invest in the feed industry but aren't sure how to turn it into a profitable business, here are three models you can consider:

1.Purchase a Single Machine

If you're already raising poultry, you can start by buying an animal feed pelletizer to meet your own needs. You can sell any extra feed to nearby small-scale farmers. This helps reduce your own feed costs while generating additional income.

2.Set Up a Small Poultry Feed Mill

Once you're more familiar with the market, you can open a small feed mill. By adding a full production line, you can scale up from a single machine to meet larger market demand. You can also expand your product range and offer custom feed formulas for different customers.

For example, you can produce feed tailored to different animals, such as pigs, poultry, ruminants, or fish. You can also offer different pricing levels based on the size and budget of each farm.

3.Partner with Others

If you're concerned about investment risk, consider partnering with an existing small feed mill or livestock farmer. By investing together, you can lower startup costs and share the risk.

You can jointly purchase equipment, build a production line, and share resources. This helps you cut costs, increase output, and reach more customers. It also makes it easier to grow your market share.

Profit and Return Analysis

Based on an individual feed processor in Dar es Salaam:

Equipment Cost: Assume the purchase of a KD-210 feed pellet machine with a capacity of 200–300 kg/h. The price is about TZS 1,400,000.

Labor Cost: At least one operator is required. If you hire someone, the monthly cost is about TZS 200,000–300,000. If you run the machine yourself, this cost can be avoided.

Facility Cost: If you're buying a single machine, you can place it in your own yard or farm building, so there's no extra cost for space.

Estimated Output: If the machine runs 8 hours per day for 22 working days per month, the estimated monthly output is around 40 tons. (Actual output may vary depending on market demand.)

Raw Material Cost: You can use common local crops to reduce feed costs.

Maize (main energy source): ~TZS 1,100/kg

Bran and grain husks (fiber fillers): ~TZS 400–600/kg

Protein sources: Fish meal and soybean meal are more expensive (TZS 1,600–2,000/kg). You can use local sunflower meal instead, around TZS 500/kg

Minerals and premix: ~TZS 50–100/kg

By mixing maize, bran, sunflower meal, and premix, you can keep the average cost around TZS 1,000/kg.

Feed Selling Price: Broiler feed retails for about TZS 1,480–1,580/kg. Layer feed is slightly cheaper, around TZS 1,220/kg. For this estimate, we use an average selling price of TZS 1,500/kg.

Electricity Cost: The KD-210 machine has a motor rated at 7.5 kW. Running 22 days per month uses about 1320 kWh. At the September 2024 commercial electricity rate (~TZS 236.37/kWh), the monthly electricity bill is about TZS 312008.

Gross Profit: (TZS 1,500 – TZS 1,000) × 40,000 – TZS 312,008 = TZS 19,687,992 per month

Note: This estimate assumes full capacity and all products sold. Labor, transport, and other costs are not included. Actual profit may vary.

Kawise Pellet Equipment - Growing Forward with You

Poultry feed production is a growing business with steady, long-term demand. It offers strong income potential and won't go out of style anytime soon.

As a professional pellet machine manufacturer based in China, Kawise offers a range of popular animal feed equipment. Our flat die and ring die pellet machines have been shipped to countries such as Tanzania, Indonesia, Zambia, and Bangladesh, helping customers produce their own feed or start feed pellet businesses from scratch.

We don't just sell machines - we provide complete, customized feed processing solutions. With expert service and technical support, we assist investors in every step: market analysis, plant layout, process design, equipment manufacturing, on-site installation, training, and technical consulting. Our goal is to ensure your feed production line runs efficiently and stays reliable for the long term.

As you explore opportunities in feed production, Kawise is here to be your trusted partner. We look forward to working with you to unlock the full potential of Tanzania's poultry feed industry-and build a successful future together.