The KAWISE Diesel Pellet Mill handles a wide range of materials, including corn, soybean meal, livestock manure, and more. Its rugged design makes it perfect for remote locations, off-grid areas, and tough terrains. Ideal for farms, ranches, and waste processing, this machine delivers reliable performance wherever you need it.

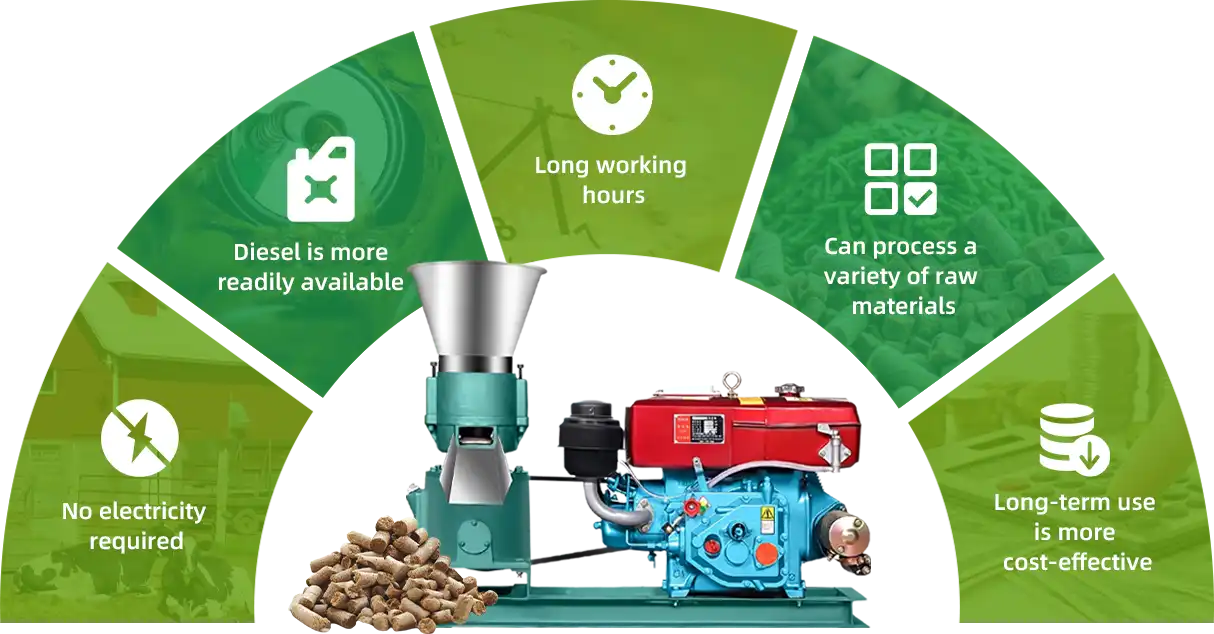

Key Benefits of the Diesel Pellet Machine

- Flexible and mobile operation: No electricity required, making it ideal for off-grid areas or mobile production. It can be used anytime, anywhere.

- Processes various raw materials: Suitable for processing feed, biomass, organic fertilizer, and more. It easily adapts to different production requirements.

- High-efficiency and stable production: Powerful diesel engine ensures long-lasting, efficient operation for continuous production.

- Diesel is easy to get: Diesel is often easier to access than electricity, especially in remote areas where power supply is unreliable.

- Cost-effective in the long run: Diesel pellet machines have slightly higher running costs. However, they are more economical in areas without electricity or where power is expensive.

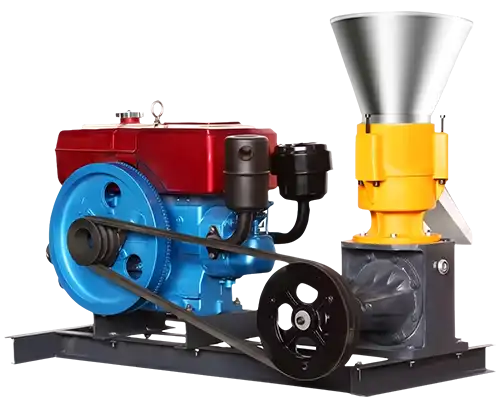

Working Principle of the Diesel Pellet Mill

The diesel pellet machine is powered by a diesel engine. After starting, the engine creates high torque by burning fuel. This drives the main shaft using a belt or gear system.

The main shaft turns the press rollers, which apply steady pressure. This pressure compresses raw materials into the die and forms high-density pellets. You can adjust the fuel supply to control the machine's speed and efficiency.

Pelletizing Process of the Diesel Pellet Mill

- Mix the raw materials evenly.

- Start and preheat the machine, then feed the mixed raw materials into the machine through the inlet.

- Driven by diesel power, the raw materials are compressed into pellets by the machine and discharged through the outlet.

- Allow the pellets to cool naturally and store them in a dry, well-ventilated area.

KAWISE Diesel Pellet Mill Models and Production Capacities

To meet different production scales, KAWISE offers a variety of diesel pellet mill models. Below is a quick comparison to help you choose the right fit.

|

Model |

Power (HP) |

Capacity (KG/H) |

Roller |

Die Hole (MM) |

|

KD-125A |

8 |

60-100 |

2 |

2.5-8 |

|

KD-150A |

8 |

80-150 |

2 |

2.5-8 |

|

KD-160A |

8 |

130-200 |

3 |

2.5-8 |

|

KD-180A |

8 |

150-220 |

4 |

2.5-8 |

|

KD-210A |

15 |

200-250 |

2 |

2.5-8 |

|

KD-210A 3R |

15 |

200-300 |

3 |

2.5-8 |

|

KD-230A |

18 |

250-400 |

3 |

2.5-8 |

|

KD-260A |

22 |

300-450 |

3 |

2.5-8 |

|

KD-260A 4R |

25 |

300-500 |

4 |

2.5-8 |

|

KD-300A |

35 |

500-700 |

4 |

2.5-8 |

Tips for Using the Diesel Pellet Mill

- Let the diesel engine idle for 3-5 minutes before use. This helps it reach optimal temperature and reduces cold-start wear.

- Use diesel that meets the required specifications to enhance engine efficiency and extend equipment lifespan.

- Clean the mold before and after use to prevent die hole clogging.

- Let the diesel engine idle for 2-3 minutes before shutting down. This helps lower the temperature and prevents damage from sudden stops.

More Support: After purchase, we provide a detailed user manual and expert support to help you quickly master operating skills. enquire now

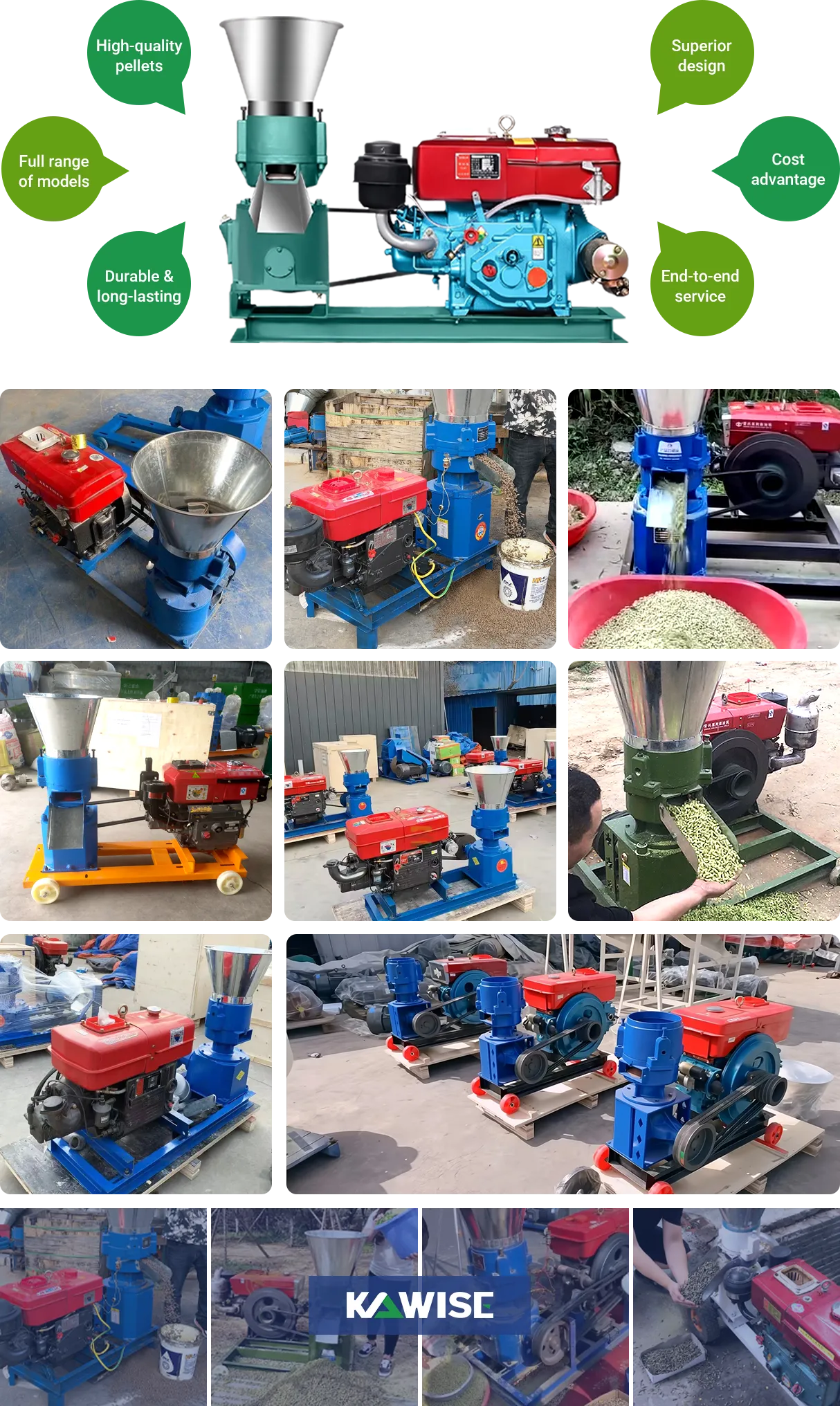

Why Choose KAWISE

- High-quality pellets:The KAWISE diesel pellet machine ensures a high forming rate. It produces smooth, dense pellets that burn efficiently and last longer.

- Full range of models: Various options available to meet different production scales.

- Durable & long-lasting: Built with high-quality alloy steel rollers and dies for reliable long-term operation.

- Superior design: Equipped with an advanced power transmission system, it reduces energy consumption, making production more economical and efficient.

- Cost advantage: Made in China, KAWISE offers high quality at a competitive price.

- End-to-end service: We provide model selection, installation, operation training, and after-sales support to ensure worry-free use for our customers.

If you need efficient production in off-grid environments, the KAWISE diesel pellet machine is your best partner. Contact us today and start your hassle-free production journey!