India's vast water resources, tropical climate, and strong government support make it one of the world's most promising countries for aquaculture. As industry grows rapidly, the demand for high-quality fish feed and efficient production equipment is rising fast. This creates a major opportunity for fish feed making machines.

The Growing Potential of India's Aquaculture Market

Rapid Expansion of Fish Farming

India's aquaculture industry is experiencing rapid growth, with over 85% of production coming from freshwater farming. The main freshwater species include Indian carp, tilapia, and pangasius, while marine aquaculture is largely focused on shrimp and tiger prawns. According to data from IMARC Group, India's aquaculture production reached 14.4 million tons in 2024 and is projected to double to 28.8 million tons by 2033.

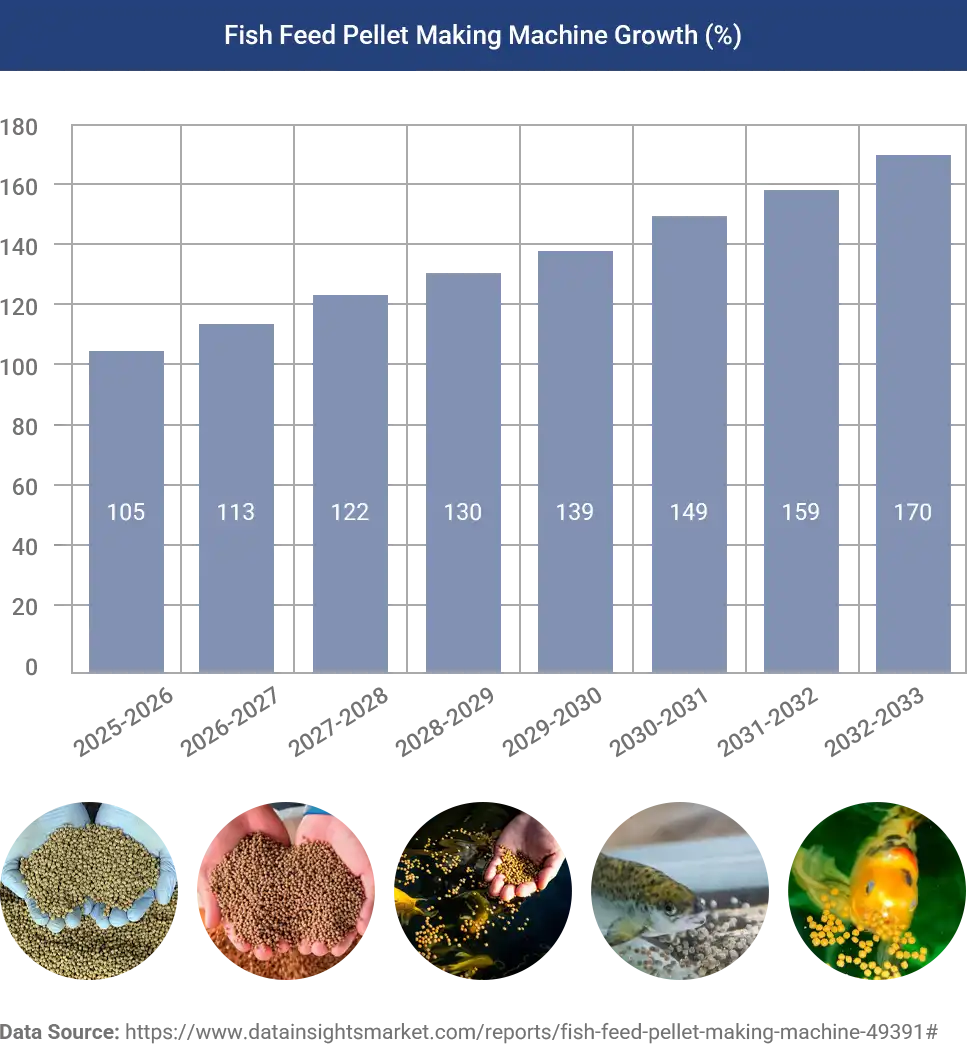

Rising Demand for Fish Feed Machine

With this growth comes a need for better, more affordable feed. The fish feed pellet machine market is growing rapidly, driven by trends like smart farming, automation, and traceable food safety. The market is expected to see double-digit annual growth through 2033.(Di Market)

Strong Policy Support Driving Growth

The Indian government is backing aquaculture through subsidies, simplified regulations, and import tax cuts. Investment in modern farming infrastructure and farmer training further strengthens the sector's competitiveness.

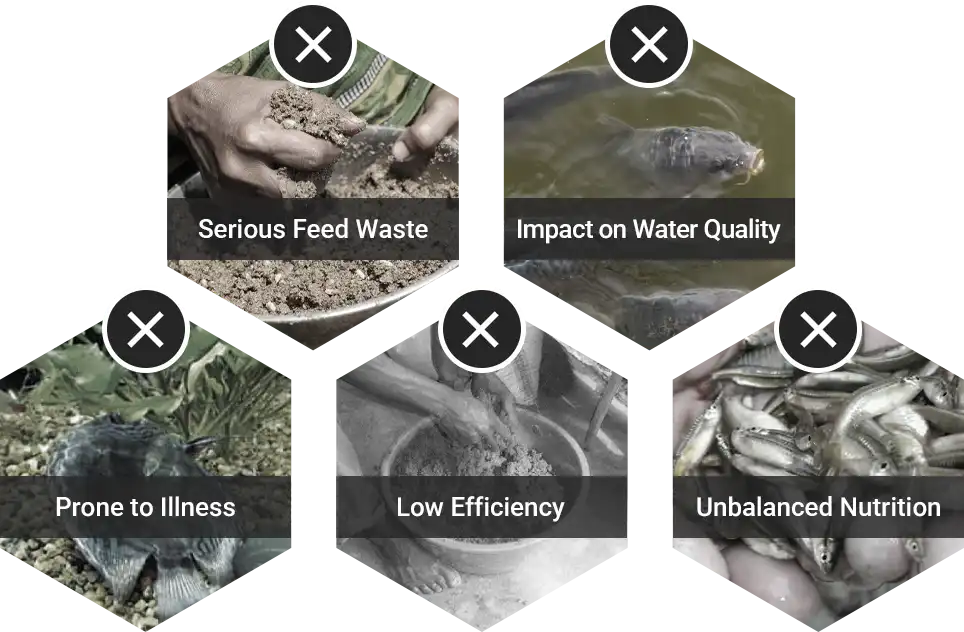

Challenges in India's Traditional Fish Feed Production

Despite rapid growth, traditional feed production methods face five major challenges:

1.Slow Growth and Feed Waste

Traditional fish feed dissolves too quickly in water, making it hard for fish to fully absorb nutrients. This leads to significant feed waste and slows down fish growth, reducing overall farm productivity.

2.Poor Feed Quality Affects Water

Many conventional feeds contain too many impurities or poorly digestible ingredients. This not only harms fish' health but can also cause water pollution.

3.Frequent Fish Diseases and Rising Costs

Low-quality feed weakens fish immunity, making them more prone to disease outbreaks. As a result, production costs rise due to increased mortality and treatment needs.

4.Low Efficiency and Limited Output

Outdated, manual feed production methods lack automation and advanced processing, leading to low production efficiency and an inability to meet growing demand.

5.Poor Nutritional Match

Different fish and shrimp species have different dietary needs. Traditional feed often fails to meet these specific requirements, resulting in either nutrient deficiency or excess-both of which hinder healthy growth.

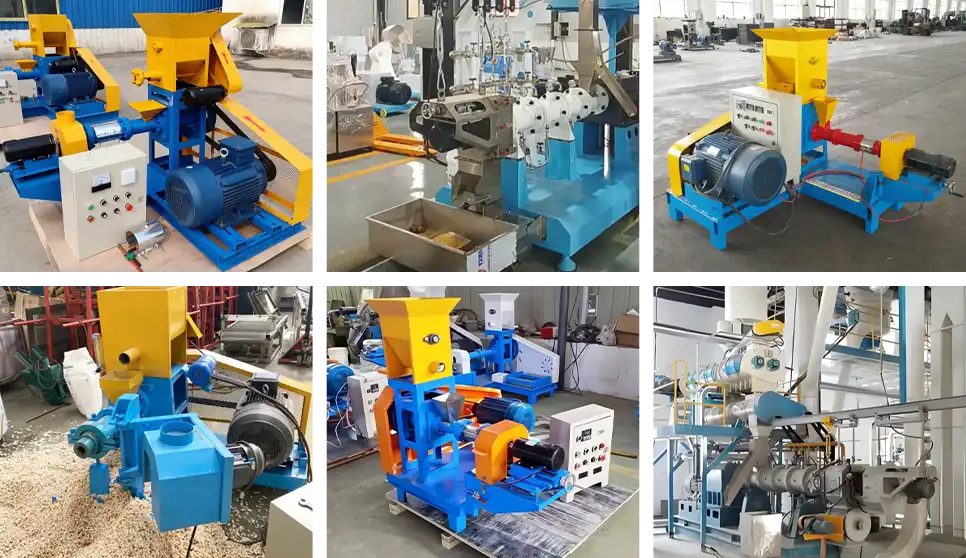

Fish Feed Extruder: The Solution to Above Challenges

How It Works

Feed extruders solve these problems through a more efficient, high-tech process. Using high-temperature, high-pressure extrusion, the machines turn raw ingredients into highly digestible, nutrient-rich pellets. This not only boosts feed quality but also cuts waste and improves farm productivity.

8 Key Benefits of Using Fish Feed Extruder Machine

Compared to traditional feed methods, extruders offer:

- High Output: Automated systems meet the needs of large-scale farms.

- Better Ingredient Use: Maximize raw material efficiency, reduce costs.

- Uniform Quality: Even nutrient distribution for better fish growth.

- Less Pollution: Higher digestion rate means fewer leftovers polluting ponds.

- Tailored Nutrition: Formulas tailored for specific fish and shrimp.

- Easy to Use: Smart controls make operation simple.

- Energy Efficient: Built with sustainability in mind.

- Sizes Fits Any Farm Size: Flexible setup to suit farms of all scales.

Tailored Feed Formulas for Indian Aquaculture

Based on India's most common farmed species, here are suggested feed types and formulas:

| Species | Pellet Size | Feed Type | Recommended Formula (%) |

| Tilapia | 2–4 mm | Floating fish feed | Fish meal 10, Soybean meal 30, Corn 30, Wheat flour 20, Fish oil 3, Premix 7 |

| Indian Carp | 3–5 mm | Semi-floating | Peanut cake 20, Rice bran 20, Soybean meal 25, Corn 20, Wheat bran 8, Vegetable oil 3, Premix 4 |

| Rohu | 3–6 mm | Floating fish feed | Fish meal 15, Corn gluten 25, Soybean meal 25, Wheat bran 20, Vegetable oil 5, Premix 10 |

| Catla (catfish) | 4–6 mm | Sinking fish feed | Fish meal 25, Chicken meal 10, Soybean meal 30, Corn 15, Fish oil 5, Wheat flour 5, Premix 10 |

| Shrimp | Micro size | Sinking fish feed | Fish meal 30, Shrimp shell powder 10, Soybean meal 25, Wheat flour 10, Fish oil 5, Additives 20 |

Fish feed formulation can be adjusted for different stages, water conditions, and growth targets.

Success Stories from Indian Fish Farms

Tamil Nadu: Boosting Output with Extrusion Tech

📍Tamil Nadu | Sundaram Aqua Tech (Mid-Sized Fish Farm) | 180 Acres

Sundaram Aqua Tech primarily farms tilapia and catla across 180 acres of ponds. As operations expanded, their traditional manual feed production could no longer keep up with demand. They urgently needed a solution that could boost production efficiency, improve feed quality, and reduce overall costs.

Solution: Two KP-80 extruder machines, integrated with a full production line.

Customer Feedback

"Our production capacity improved a lot. Shrimp feed quality is better, and fish are growing faster. We've saved on costs too. A worthwhile investment!"

Andhra Pradesh: Healthier Shrimp, Higher Yield

📍Andhra Pradesh | Shrimp Farming Co-op | Traditional Feed Methods

Solution: A complete feed production line equipped with a KP-60 extruder machine.

Customer Feedback – Shrimp Farmer, Andhra Pradesh

"We used to make feed the old way-quality wasn't great, and the shrimp often got sick with things like white spot or black gill. Since using this machine, the feed's much more consistent, the shrimp grow faster, water quality is better, and we've had fewer disease problems. It's been a really good upgrade for us."

Custom Solutions and Full Support

We offer customized solutions tailored to the specific needs of India's aquaculture market. Whether you're running a small family farm or a large commercial operation, our technology helps ensure efficient feed production.

We also provide comprehensive after-sales support-including maintenance, technical training, and troubleshooting-so you can operate with confidence.

Looking to boost your farm's efficiency? Our fish feed extruder solutions are designed to support sustainable and high-yield aquaculture in India. Feel free to contact us for inquiries and collaboration.

| Floating fish feed |