Waste paper is one of the most common types of household waste. While much of it is technically recyclable, the process often requires complex sorting and strict standards. As a result, a large portion of waste paper ends up in landfills, accounting for about 26% of global solid waste.

Even when successfully collected, paper fibers can only be recycled a limited number of times. As the fibers become shorter and the quality declines, they eventually lose their value for papermaking and must be discarded.

In this context, turning waste paper into pellets using a biomass pellet machine offers a simpler and more energy-efficient alternative. It skips the need for pulping or chemical bleaching. With just a few basic steps, the processed pellets can be used in a variety of applications-making it both eco-friendly and economically practical.

What You Can Do with Paper Pellets

You can use paper pellets in many practical ways:

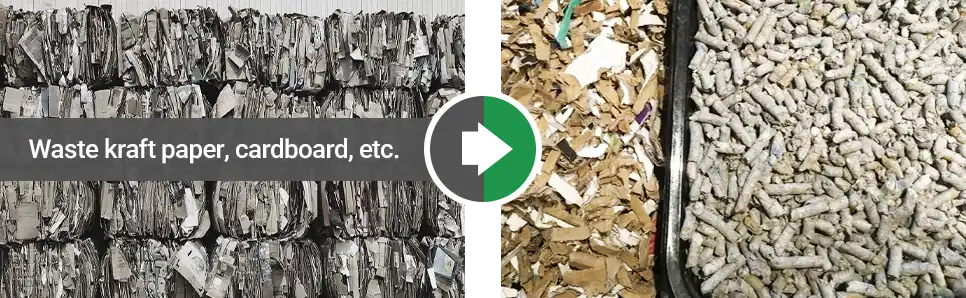

1.Alternative Fuel

Waste paper can be used to make biomass fuel pellets. Different types of paper have different compositions, so their energy content varies too. On average, dried paper pellets have a heating value of 12–18 MJ/kg (about 2,900–4,300 kcal/kg).

Common sources include newspapers, office paper, envelopes, kraft paper, drink cartons, cardboard, and more. These materials are easy to source and need little processing before use. The pellets can be burned in stoves, boilers, and other heating systems. They work well as a partial replacement for wood pellets or coal.

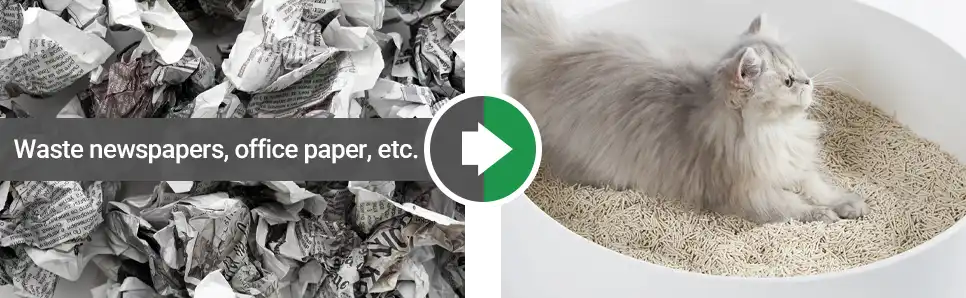

2.Paper Pellet Cat Litter

One popular way to reuse waste paper is by turning it into pellet cat litter. These pellets are usually made from soft-fiber paper like newspapers and office paper, using inks that are safe for pets. They're designed to be highly absorbent and low in dust, which helps protect a cat's respiratory health.

Used litter can also be composted, making it part of a more eco-friendly waste cycle. Compared to traditional clay litter, paper pellets are a cleaner, greener choice.

3.Pet Bedding

Waste paper can also be used to make pellet bedding for small pets like rabbits, hamsters, and guinea pigs. Unlike wood shavings, paper bedding doesn't contain resins or essential oils. This makes it safer for animals that are sensitive to smells or prone to allergies.

The pellets are firm and absorbent, making them ideal as bedding. After use, they can be composted as organic waste. It's a simple and eco-friendly way to reuse waste paper.

4.Gardening Use: Moisture Retention

Paper pellets can be used in gardening to help retain moisture. They work well in seed-starting mixes or as a soil cover. These pellets absorb water and slowly release it around the roots, helping keep the soil damp and reducing how often you need to water.

Used as mulch, they can also help block weeds and regulate soil temperature. Since they're biodegradable, the pellets gradually break down into organic matter, which helps improve soil structure. It's a simple, eco-friendly way to reuse paper and support healthy plant growth.

Benefits of Turning Waste Paper into Pellets

Turning waste paper into pellets brings several practical benefits:

- It reduces the amount of paper going to landfills, which helps ease pressure on waste systems and makes better use of discarded paper fibers.

- When used as fuel, paper pellets burn more cleanly than coal. Their lower sulfur and nitrogen content helps reduce acid rain and other pollution.

- For uses like cat litter or pet bedding, pellets are easy to handle and measure. They can be composted after use, supporting a more sustainable cycle.

- Waste paper is easy to collect, and the pelletizing process is simple. With relatively low equipment costs, this solution is well-suited for small-scale users.

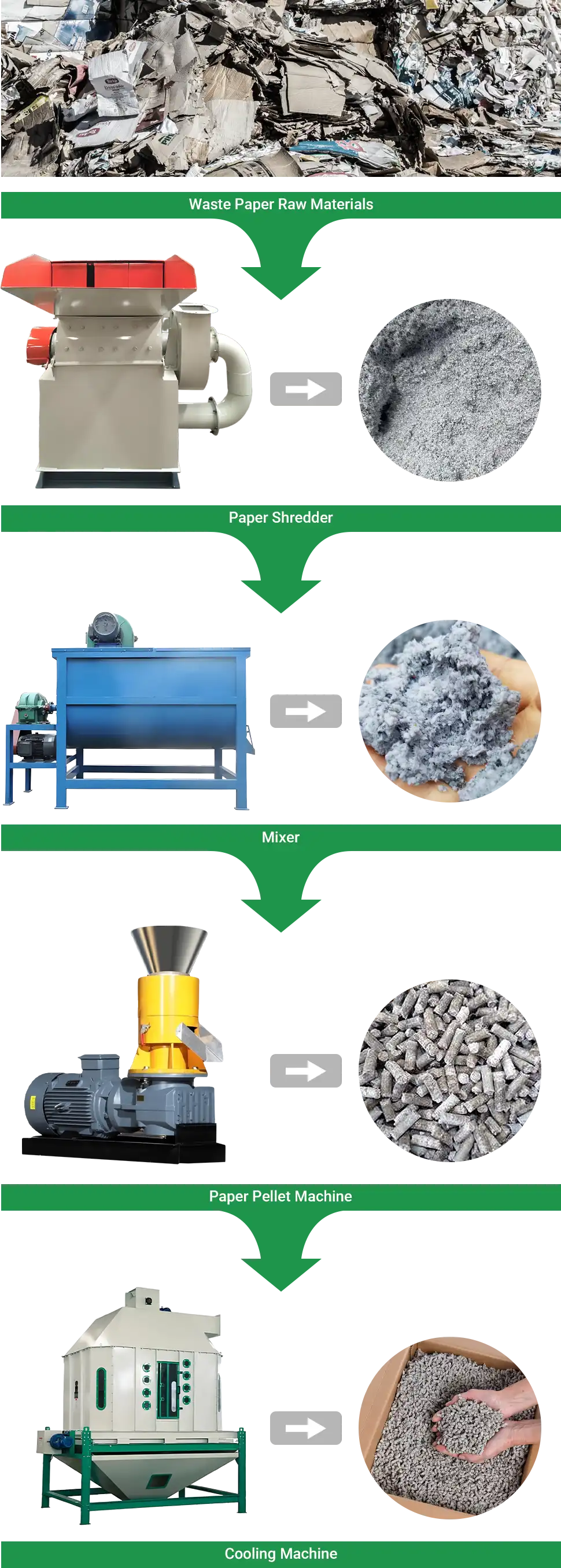

How to Make Paper Pellets

Making paper pellets is a fairly simple process. Unlike traditional papermaking, it doesn't require strict sorting-most types of waste paper can be mixed and used together. After shredding and mixing, the material goes into a pellet machine. The newly formed pellets are then cooled and screened to remove dust and fine particles before being stored for use.

If you're making pellets for cat litter or pet bedding, it's better to sort the paper in advance. Choose soft-fiber materials with pet-safe ink to improve absorbency and ensure safety.

A typical paper pellet production line includes four main machines:

- Paper shredder: Cuts waste paper into small, manageable pieces.

- Mixer: Evenly blends different paper types for consistent pellet quality.

- Pellet machine: Compresses the mixed material into solid pellets.

- Cooler: Cools the pellets after forming and helps remove fine dust.

Among these, the pellet machine plays the most important role. Pellet quality depends not only on the raw material but also on the machine itself. A reliable pelletizer improves forming rate and output while reducing waste and energy use.

Kawise Paper Pellet Machines for Sale

Based in China, Kawise has years of experience in biomass pellet machine manufacturing. Our machines are built to handle light materials such as waste paper and sawdust, making them a great fit for paper pellet production.

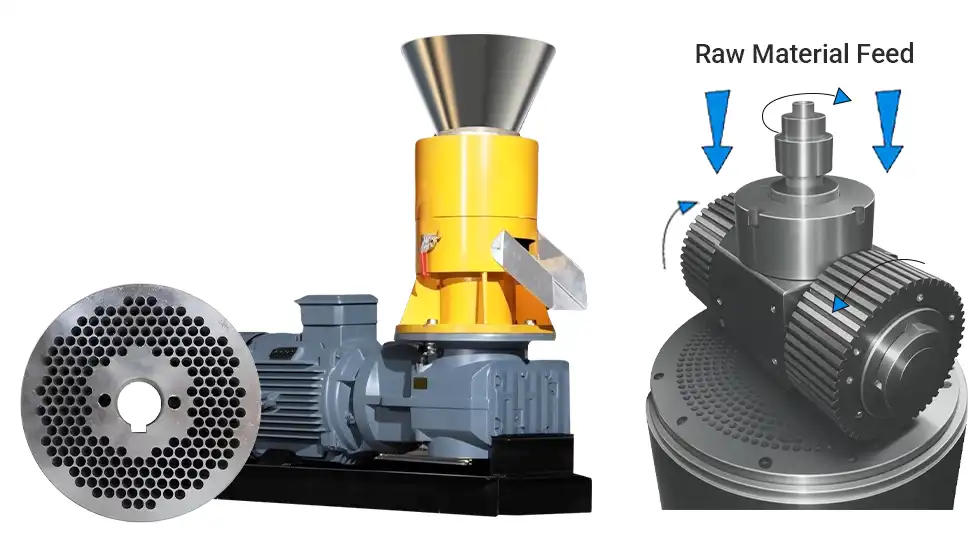

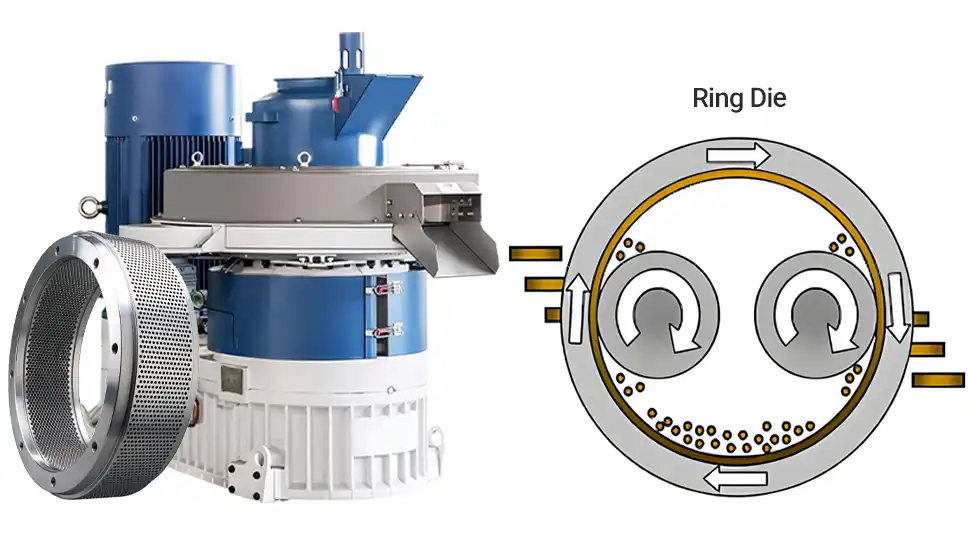

We offer two types of pellet machines: flat die and ring die models. Flat die models are easy to use and affordable, making them ideal for individuals or small startups. Ring die models offer higher output and are better for continuous production.

Flat Die Paper Pellet Making Machine

| Model | Power (kw) | Capacity (kg/h) | Total Weight (kg) |

| KB-250 | 15 | 100-200 | 400 |

| KB-300 | 22 | 200-300 | 800 |

| KB-350 | 30 | 300-400 | 900 |

| KB-400 | 37 | 400-600 | 1000 |

| KB-450 | 45 | 600-800 | 1500 |

| KB-550 | 55 | 700-1000 | 1800 |

Ring Die Paper Pellet Making Machine

| Model | Power (kw) | Capacity(t/h) | Weight (t) |

| KH-450 | 75 | 0.7-1 | 4 |

| KH-560 | 90 | 1-1.5 | 6.5 |

| KH-680 | 160 | 1.5-2.5 | 8.5 |

| KH-850 | 220 | 2-3.5 | 12.6 |

| KH-880 | 315 | 3.5-4.5 | 14.5 |

With Kawise, you get:

- Our machines deliver reliable performance. Key parts are made from wear-resistant alloy steel and go through precision machining and heat treatment. This improves durability and lowers long-term maintenance costs.

- You enjoy factory-direct pricing. All machines are sold directly from our facility, offering excellent value without middlemen.

- We offer tailored solutions. With over 20 years of experience, we can recommend the right model and setup based on your specific needs.

- You receive thoughtful after-sales support. Every machine includes a 12-month warranty (excluding wear parts), installation guidance, and remote technical support. On-site service is also available if needed.

Turning waste paper into pellets isn't just good for the environment-it's also simple to start and pays off in the long run.

Get in touch today to launch your paper pellet project and move toward a cleaner, more efficient future. enquire now

FAQ

- Does the moisture content of the raw material matter?

Absolutely. For smooth pelletizing and firm results, the moisture level should be around 10%. After pelletizing, it's important to dry or cool the pellets until the moisture drops below 10%. This is especially critical for cat litter pellets, which need to stay dry to prevent mold, clumping, or poor burning performance.

- Do temperature and pressure need to be controlled during pelletizing?

Yes, both temperature and pressure matter. During operation, the temperature should stay between 60–70°C. This softens the paper fibers and improves pellet formation. If it's too low, pellets may turn out loose. If it's too high, the fibers can burn or release odors.

For fuel pellets, higher pressure increases density and heating value. For cat litter, lower pressure keeps the structure more porous. This boosts absorbency and makes the pellets easier to break down after use.

- What size should paper pellets be?

That depends on the application, but keeping the size consistent is key.

Fuel pellets are typically 6–8 mm in diameter and 10–30 mm in length. If they're too long, they may break or cause feeding issues.

Cat litter pellets are best at 4–6 mm in diameter and about 10 mm long, making them easy for cats to walk on and bury.

- Can all types of waste paper be used to make pellets?

Not all paper works well. Glossy prints, laminated packaging, or paper with coatings can clog the machine or release harmful gases when burned. It's best to stick with clean, soft-fiber paper like newspapers, office paper, or cardboard. These are safer to process and produce better-quality pellets.