The die is a crucial part in pellet forming, directly affecting density, yield, energy consumption, and machine lifespan. Choosing the right die boosts output, saves energy, and reduces maintenance. With so many options and varying quality, it's easy to make the wrong choice. Below, we'll highlight key factors to help you make an informed decision.

Core Function and Types of Pellet Mill Dies

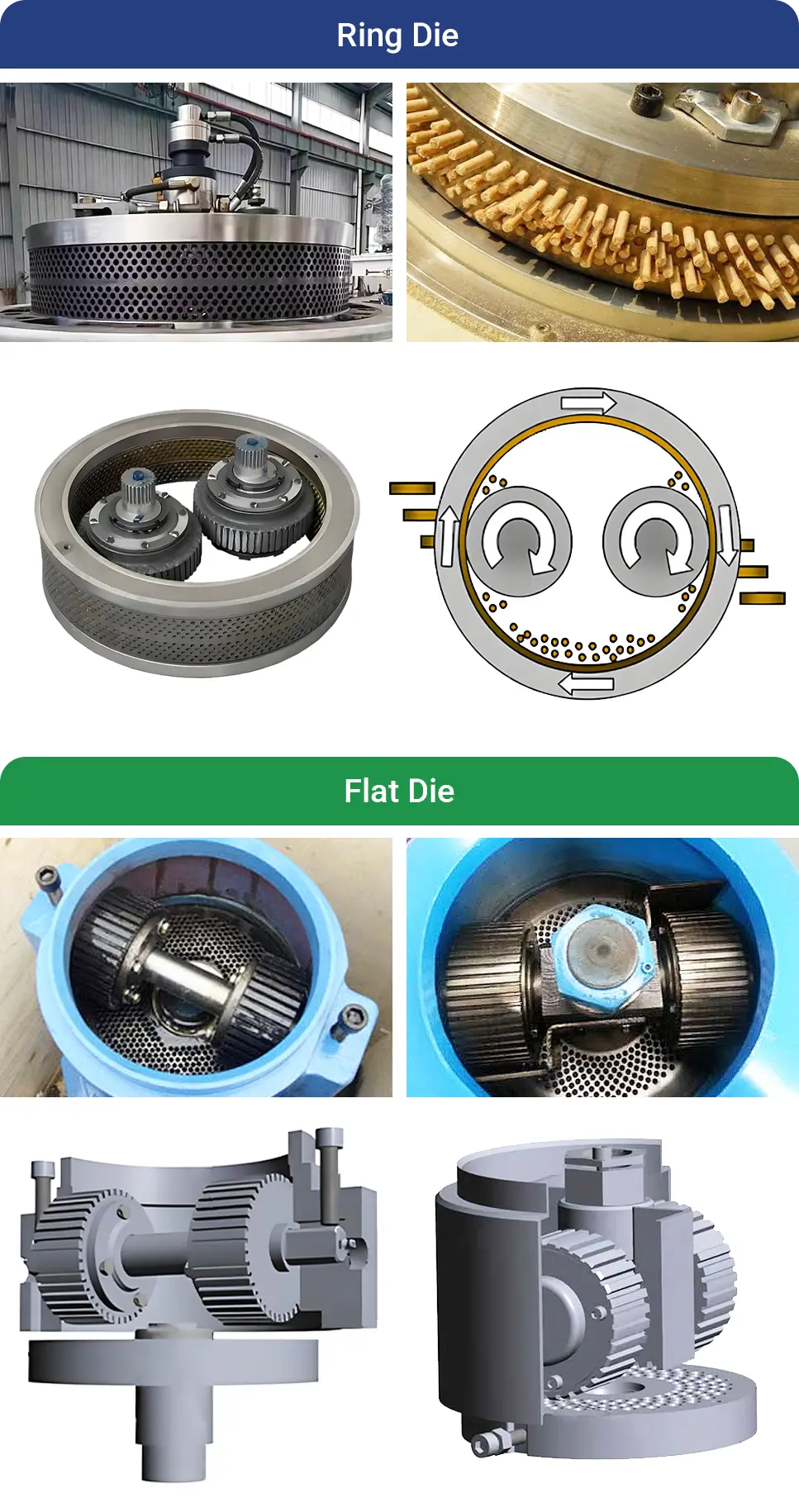

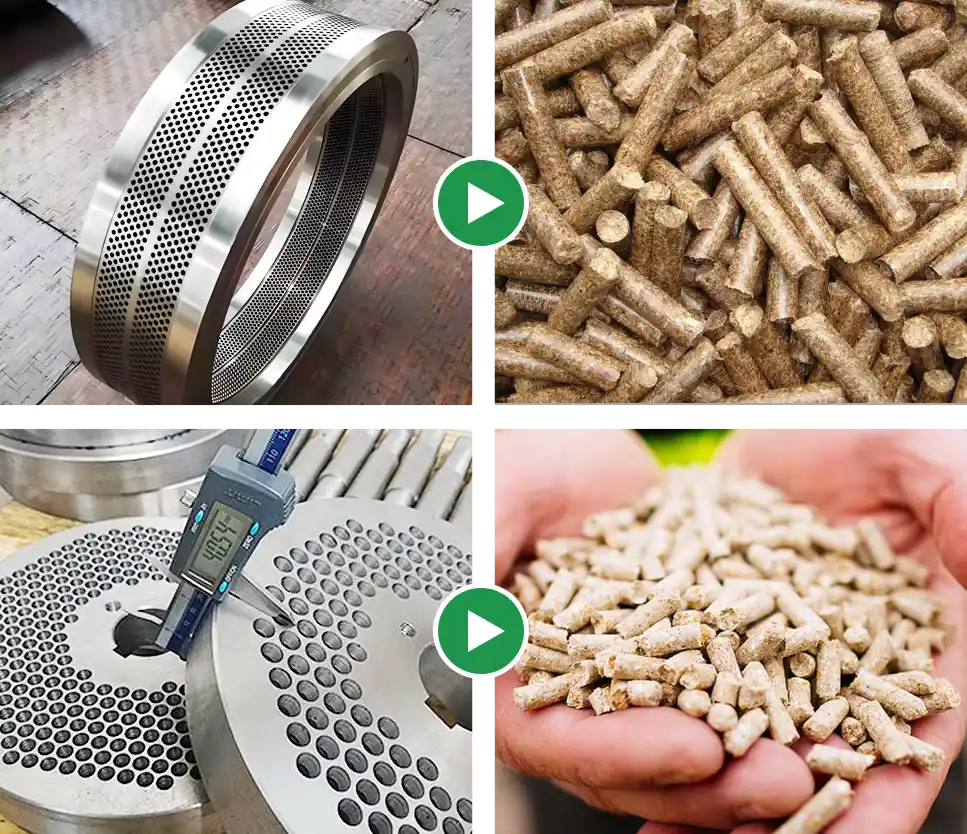

The pellet mill die (also called press die set, ring die, or flat die) is essential in pellet production. It has holes through which material is pressed into compact pellets by the rollers. Pellet dies are mainly divided into:

Ring Die: Used in large-scale, continuous production. Material is pressed on both sides of the ring, and pellets are extruded from inside out or outside in.

Flat Die: Used in small-scale, intermittent production. Material is pressed on the top surface, and pellets are extruded from top to bottom.

Key Parameters You Should Know

Choosing a die isn't just about price. It's important to consider factors like material, hole size, compression ratio, and production process. These directly affect pellet quality and production efficiency.

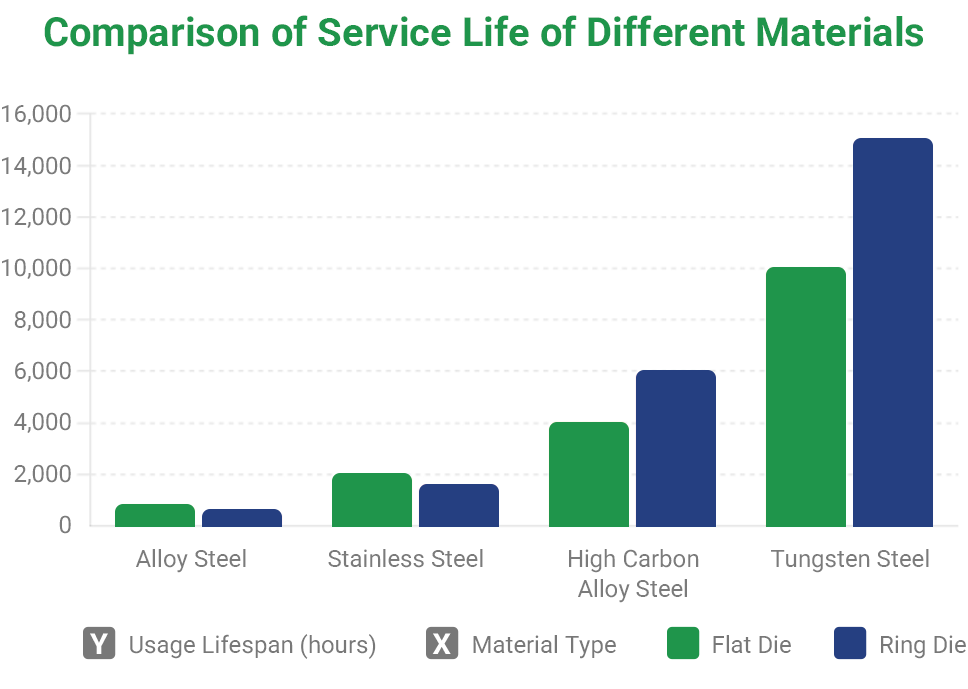

Material and Lifespan

The material of the die affects both cost and lifespan. It also impacts production stability. The hardness, moisture, and impurity levels of the raw materials can affect die wear.

Carbon Steel (e.g., Q235)

Low cost, but wears easily. Suitable for low-output applications where die lifespan is less of a concern.

Alloy Steel (e.g., 40Cr, 20CrMnTi)

Improved strength, hardness, and wear resistance through alloy elements like chromium, manganese, and titanium. This is the most common choice.

Stainless Steel (e.g., 3Cr13, 4Cr13)

Excellent corrosion resistance, ideal for materials with corrosive components (e.g., certain feeds, organic fertilizers), but more expensive and slightly less hard than alloy steel.

Special Alloys (e.g. High Chromium, Nickel-based)

Designed for high wear, corrosion, or extreme conditions. Long lifespan and excellent performance, but very costly. Usually used in large industrial lines or with specific materials.

The data based on feedback and heat treatment standards, is a reference. The actual lifespan varies with die structure and materials.

Selection Tip

Tungsten carbide dies much longer than alloy steel and stainless steel, but they're much more expensive. For feed or biomass pellet production, alloy steel and stainless steel dies work well and are more cost-effective.

Hole Size and Shape

The shape of the die holes affects pellet density, hardness, smoothness, and forming speed. The hole size decides the pellet size, and different products require different sizes:

Cylindrical Holes: Create uniform pellets in size and shape, often used for feed.

Conical Holes: Reduce friction and increase density, ideal for biomass or wood pellets.

Step Holes: Combine both features to improve quality and lower energy use.

| Application | Hole Size (mm) |

| Chicken, Duck, Pig Feed | 3–4 |

| Pig, Cattle, Sheep Feed | 4–6 |

| Fish Feed (Sinking Type) | 1–2 |

| Rabbit Feed | 2.5–3 |

| Dog & Cat Pet Food | 3–5 |

| Biomass Fuel | 6–8 |

| Cat Litter Pellets | 4–6 |

| Organic Fertilizer | 3–6 |

| Livestock Manure Pellets | 3–6 |

Smaller holes aren't always better. If the material is too fibrous, small holes may cause blockages. Larger holes can reduce pellet stability and increase molding difficulty. Balance material and production needs when choosing the hole size.

Besides hole size, hole density also impacts efficiency and pellet quality. Higher density improves efficiency but can cause uneven pressure and quicker die wear.

When choosing the pellet machine die, consider factors like hole size and compression ratio to ensure pellet quality and die durability.

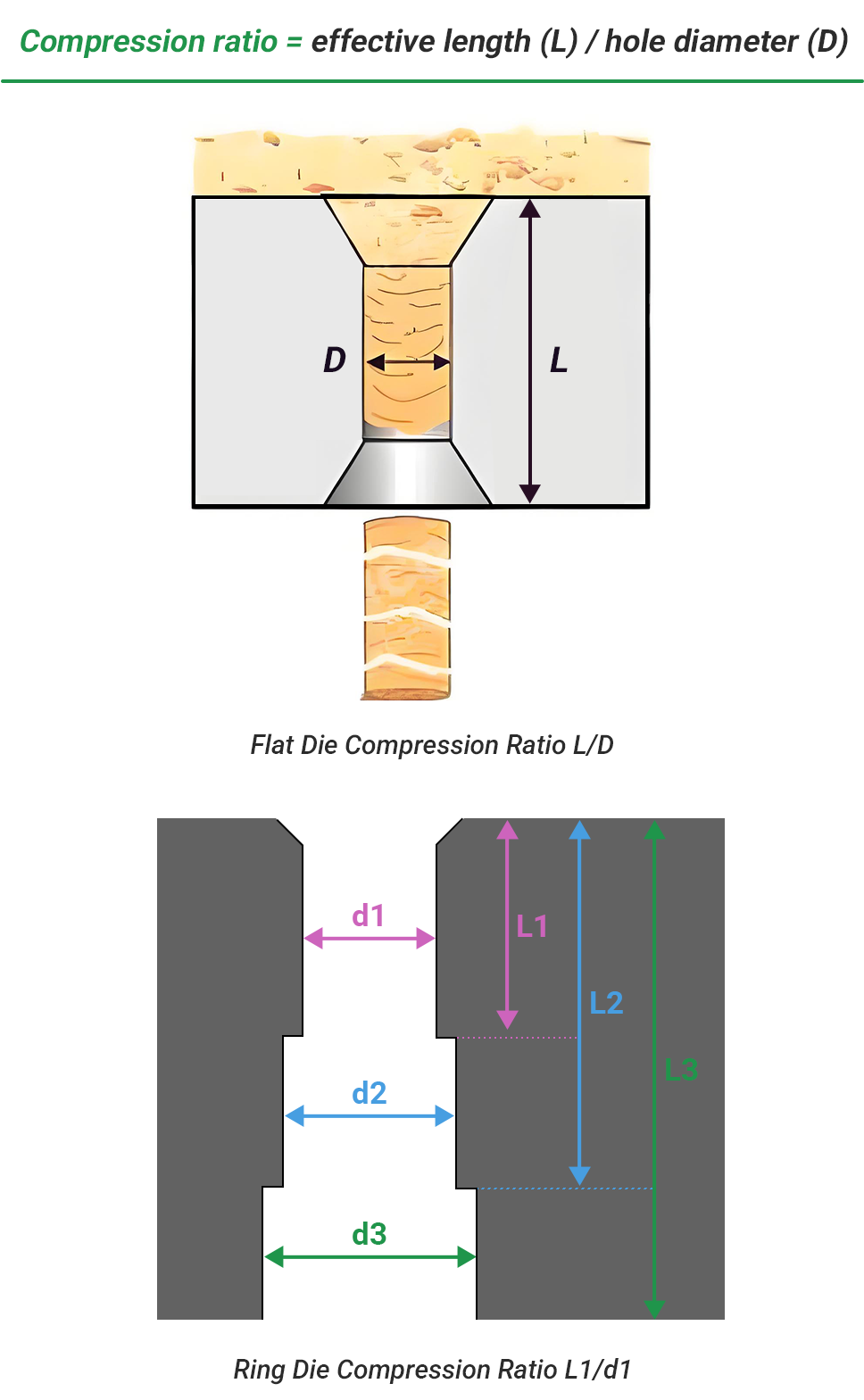

Compression Ratio

The compression ratio is the ratio of the effective length (L) of the die hole to its diameter (D). It directly affects how much the pellets are compressed in the die, impacting their density, hardness, and stability.

Although the basic formula for compression ratio is the same, the definition of effective length (L) differs between flat and ring dies due to structural differences.

In practice, both too high or too low a compression ratio can cause issues.

Too low: Pellets are loose, poorly formed, and waste material.

Too high: Difficult pellet discharge, higher equipment load, and increased energy use.

Choosing the right compression ratio is key to better pellet density and strength. It also boosts efficiency and helps extend the life of both your die and equipment.

Recommended Compression Ratio Table:

| Material Type | Flat Die L/D | Ring Die L/D |

| Corn + Soybean (Chicken Feed) | 1:10–1:13 | 1:13–1:15 |

| Pig Feed (with Bran) | 1:12–1:14 | 1:13–1:15 |

| Cattle & Sheep Feed (with Grass) | 1:10–1:13 | 1:11–1:14 |

| Grass (Alfalfa/Straw) | 1:8–1:10 | 1:10–1:12 |

| Fish Feed (Sinking) | 1:14–1:18 | 1:16–1:20 |

| Shrimp Feed (Micro-pellets) | 1:16–1:20 | 1:18–1:22 |

| Sawdust (Fuel) | 1:16–1:20 | 1:18–1:25 |

| Shells (Rice/Peanut) | 1:12–1:15 | 1:14–1:18 |

| Oilseed (Rice Bran/Cotton Meal) | 1:10–1:12 | 1:12–1:14 |

| High Moisture (Wet Soy/Distillers) | 1:8–1:10 | 1:9–1:11 |

Production Process

The production process of the die directly affects its precision, toughness, wear resistance, and lifespan. Common processes include:

Drilling: Basic hole processing with average precision.

Deep Hole Drilling: Improves hole straightness and reduces friction inside.

Vacuum Carburizing (Nitriding): Infuses carbon (or nitrogen) into the surface, creating a hard layer for better wear resistance.

Quenching and Tempering: Heat treatment to achieve optimal hardness, toughness, and strength.

High-quality dies combine deep hole drilling, vacuum carburizing, and precision grinding. When selecting a die, focus on key factors like hole precision, surface hardness, wear resistance, and heat treatment. These will ensure the die performs well and meets your production needs.

How to Quickly Assess Die Quality

Choosing the right die affects pellet formation, equipment stability, and maintenance costs. Here are key details to check before purchasing:

Device Compatibility

The die must match your pellet mill, especially at key positions like the shaft hole, keyway, and locating holes. A mismatch could lead to installation issues, instability, or damage to the spindle.

Tip: Provide your machine model, old die dimensions, or photos before purchasing to ensure a perfect fit.

Hole Cleanliness and Precision

The hole precision and smoothness affect pellet output. High-quality dies have clean, smooth, and uniform holes, with no burrs. Rough holes can lead to blockages, low output, and malformed pellets.

Quick Check: Shine light on the die surface. If it reflects evenly and the inner surface is clean and shiny, it usually indicates high processing precision.

Heat Treatment Process

Wear resistance and lifespan depend on proper heat treatment. Dies with uneven surface color, blackened or yellowed areas may not have been heat-treated properly, leading to faster wear, cracking, or deformation.

Properly heat-treated dies have a uniform, dark gray or metallic sheen with no discoloration or burn marks.

Flatness Check

The die must be flat and not deformed. An uneven die will cause wobbling, noise, or even jam the machine.

Tip: Place the flat die on a flat surface to see if it fits evenly. For a ring die, rotate it around the edges to check for eccentricity or warping.

These simple checks will help you evaluate die quality and choose the right one, reducing unnecessary risks.

Recommended Trusted Brands

Now that you know about die parameters and selection tips, you may be wondering which brands to trust. Choosing a reliable brand reduces risks. Here's a list of top die manufacturers and their key advantages to help you choose.

- CPM (USA) | Known for high performance and stability in CL and Master series dies.

- Bühler (Switzerland) | Kubex series excels in energy efficiency and high capacity.

- Andritz (Austria) | FeedMax G series adapts well to complex materials.

- Amandus Kahl (Germany) | Effective for high-density, hard-to-form materials.

- Zhengchang (China) | SZLH series offers reliable, balanced performance.

- Muyang (China) | Cost-effective dies with great value.

- Yida (China) | Focuses on precision and durability for ring dies.

- Liyang Machinery (China) | Wide variety with customization services.

When choosing a mold, think about your material, output, and budget. Also, ask the supplier about the mold material, compression ratio, production process, and after-sales service to make the right choice.

Reference for Die Selection

| Material / Use | Material | Diameter(mm) | Compression Ratio |

| Feed (Chicken, Duck, Pig) | Alloy Steel | 3–4 | 1:10–1:13 |

| Feed (Cattle, Sheep) | Alloy Steel | 4–6 | 1:10–1:13 |

| Rabbit Feed | Alloy Steel | 2.5–3 | 1:11–1:13 |

| Fish Feed (Sinkable) | Stainless Steel | 1–2 | 1:14–1:18 |

| Shrimp Feed | Stainless Steel | 0.8–2 | 1:16–1:20 |

| Pet Food (Dogs, Cats) | Stainless Steel | 3–5 | 1:12–1:14 |

| Wood Fuel | Alloy Steel | 6–8 | 1:16–1:20 |

| Rice/Peanut Shells | Alloy Steel | 5–7 | 1:12–1:15 |

| Coconut/Palm Shell | Special Alloys | 6–8 | 1:14–1:18 |

| Organic Fertilizer | Stainless Steel | 3–6 | 1:10–1:14 |

| Cat Litter | Alloy Steel | 4–6 | 1:10–1:12 |

| High Moisture Materials | Alloy Steel | 4–6 | 1:8–1:10 |