Pet rats have grown in popularity in recent years. They're small, easy to care for, and well-suited for home environments. As more people keep rats as pets, owners are paying closer attention to their diets. Many are now looking for healthier and more natural food options.

This demand is driving steady growth in the rat food market. The global market is projected to reach $100 million this year, with an average annual growth rate of 5%. Most commercial rat food falls into two main types: pellet feed and mixed feed. Pellet feed is gaining traction due to its clear formula, balanced nutrition, and ease of feeding.

If you're planning to enter the pet food market, developing a pellet-based diet for pet rats could be a smart and practical starting point.

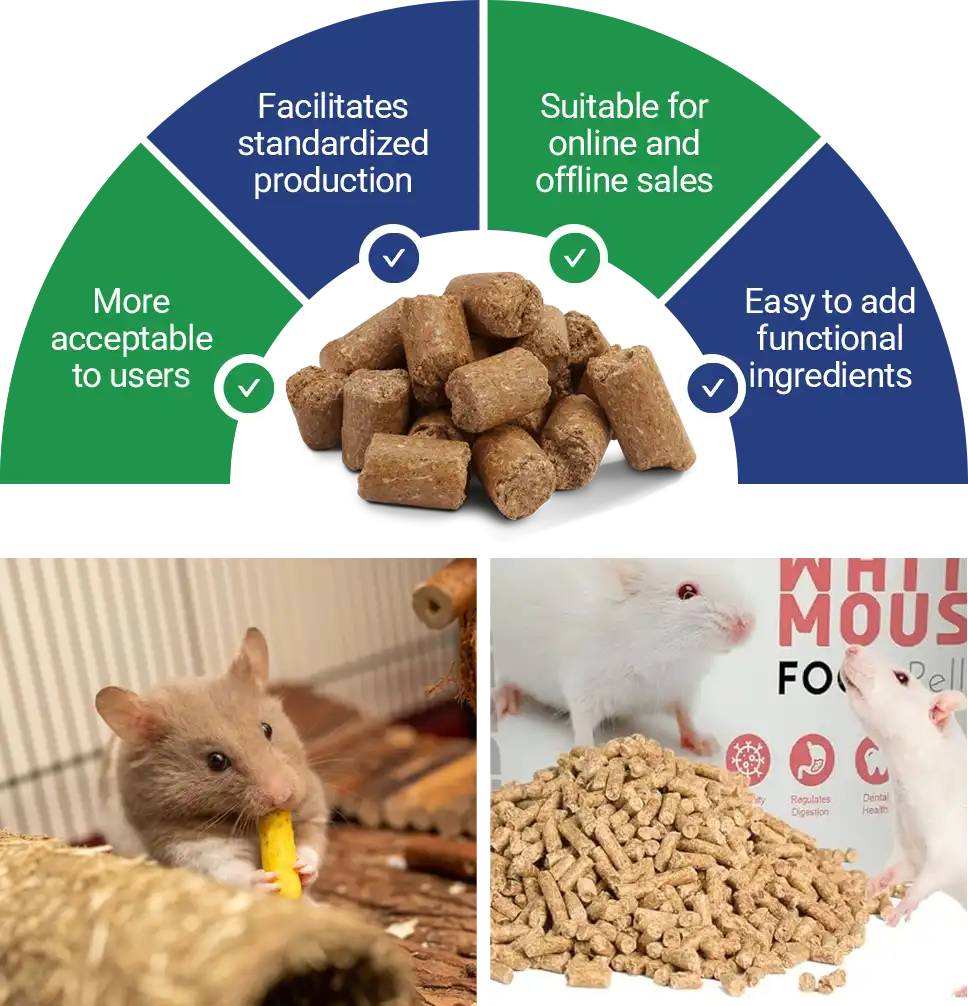

The Competitive Edge of Pellet Feed

Pellet feed refers to a type of feed made by crushing various ingredients, mixing them in specific ratios, and pressing them into uniform shapes. Its competitive edge lies in the following aspects:

- Proven and popular: Pellet feed is a mainstream choice in the global feed market, offering strong user acceptance and smoother entry for new pet food brands.

- Better for packaging and transport: With their consistent shape and dense structure, pellets are easy to pack, store, and ship-whether you're selling online or in stores.

- Supports functional upgrades: The pellet form allows for easy addition of probiotics, minerals, or other nutrients, creating room for future product line expansion.

Overall, pellet feed has a strong market foundation and promising growth potential.

To stand out, however, you'll still need to meet the specific dietary needs of pet rats.

Age-Based Pellet Formulas for Pet Rats

Pet rats have different nutritional needs at each stage of life. To create an effective and professional pellet formula, it's important to adjust the ingredients based on their age and development.

The table below highlights the basic protein and fat requirements by life stage.

| Life Stage | Protein | Fat | Key Considerations |

| Young rats (<7 months) | ≥16% | 5–8% | Support growth and development |

| Adult rats | 14–16% | 5–8% | Maintain health, avoid excess |

| Pregnant or nursing rats | ≥16% | 5–8% | Meet reproductive needs |

| Senior rats | 12–14% | 4–6% | Protect kidney health, reduce fat |

A balanced formula is key to making quality rat pellets-but the production process matters just as much.

How Pellet Feed for Pet Rats Is Made

Making rat pellets usually involves the following steps:

1.Raw Material Preparation

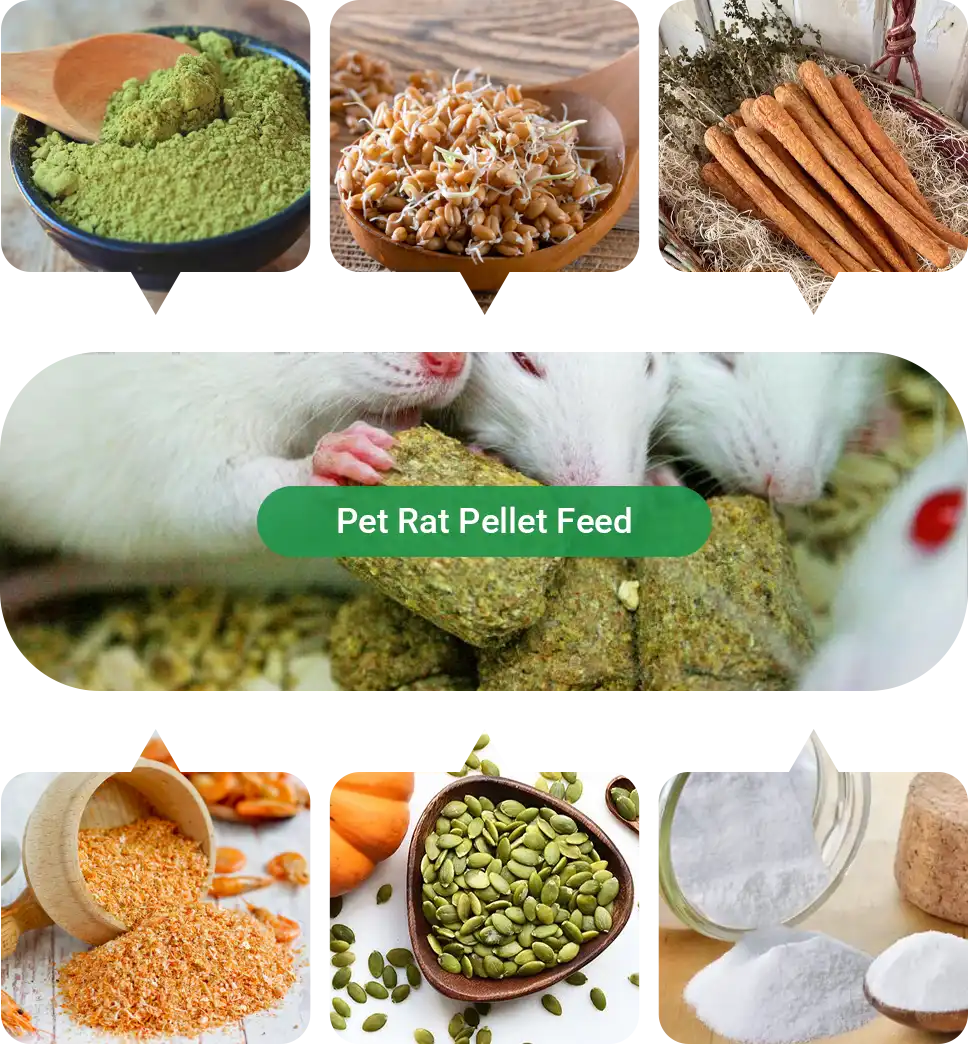

Selecting the right ingredients is the first step toward balanced nutrition. The table below lists commonly used ingredients and their typical roles in a healthy rat diet.

| Category | Example Ingredients | Usage Notes |

| Base Mix | Alfalfa meal, pea hay powder, defatted soybean meal | Forms the bulk of the formula; use high-fiber, low-fat ingredients as the base |

| Processed Grains | Unsweetened corn flakes, wheat germ, brown rice, rolled oats, crushed popcorn | Choose low-sugar types; mix 2–3 kinds to increase variety |

| Vegetables & Herbs | Dried carrot, dried beetroot, dried dandelion, parsley, dried rabbit hay mix | Provide fiber and trace nutrients; use raw-grade or homemade ingredients |

| Protein Sources | Dried insects, shrimp meal, pea protein, insect protein powder | Adjust by age; avoid excessive protein intake |

| Seeds | Pumpkin seeds, flaxseeds, sunflower seeds, sesame, peanuts | Add in moderation to supply healthy fats; watch calorie levels |

| Nutrient Add-ons | Calcium powder, Dr. Squiggles, Calcivet | Add separately to ensure balanced vitamin and mineral intake |

2.Grinding the Ingredients

Once the ingredients are ready, they're ground using a crusher to get the right texture for mixing.

The grind size can vary depending on the formula and age group. Finer particles are better for young or older rats, making digestion easier. A coarser texture can encourage chewing in healthy adults.

3.Mixing the Ingredients

The ground materials are then mixed using a feed mixer based on the set formula. Good mixing ensures all nutrients are spread evenly. This helps produce uniform pellets, so rats get balanced nutrition in every bite.

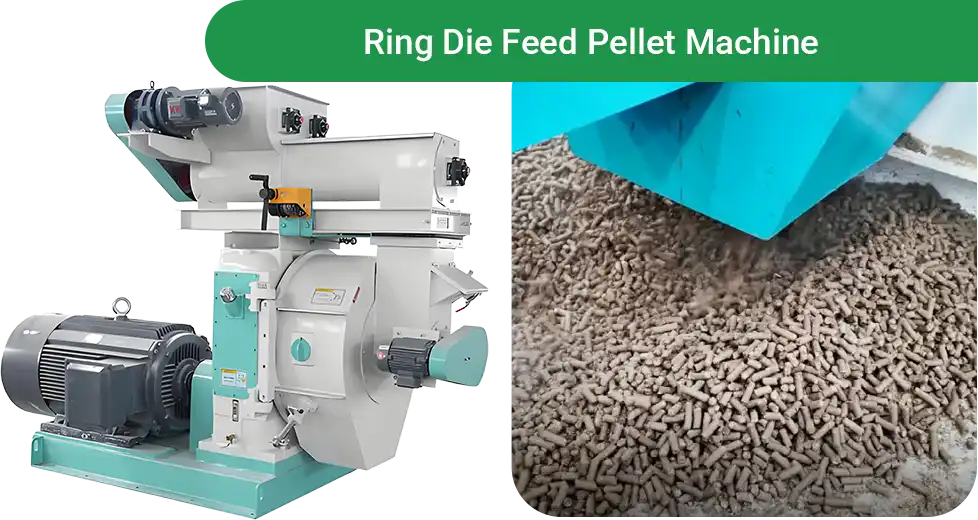

4.Pelletizing

The blended mix is fed into a pellet mill, where heat and pressure compress it into small, chewable pellets.

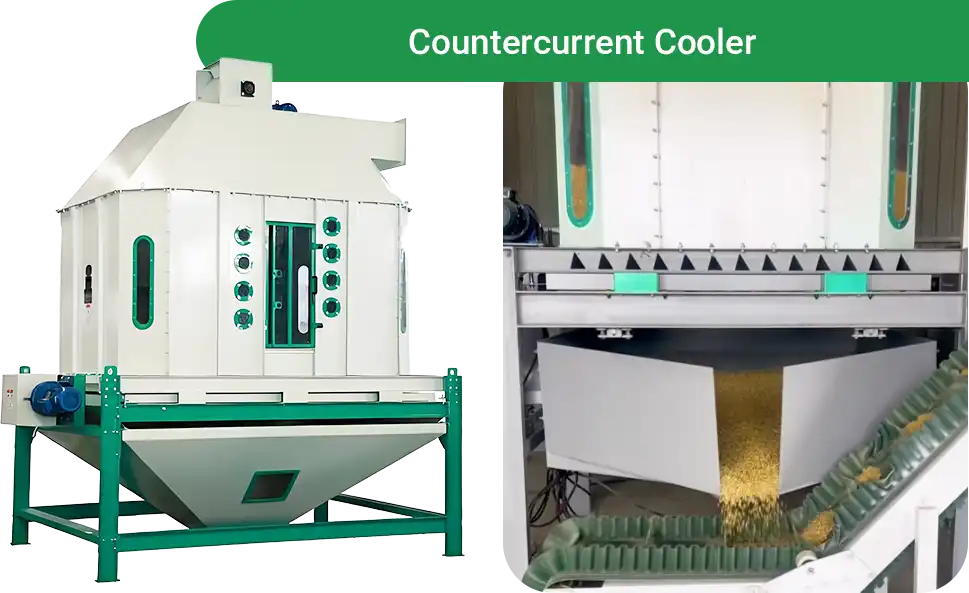

5.Cooling and Drying

Fresh pellets are still hot and moist, which can cause mold. They need to be fully cooled and dried before storage.

This is usually done with a cooler or dryer. The goal is to keep the pellets dry, firm, and safe for long-term storage.

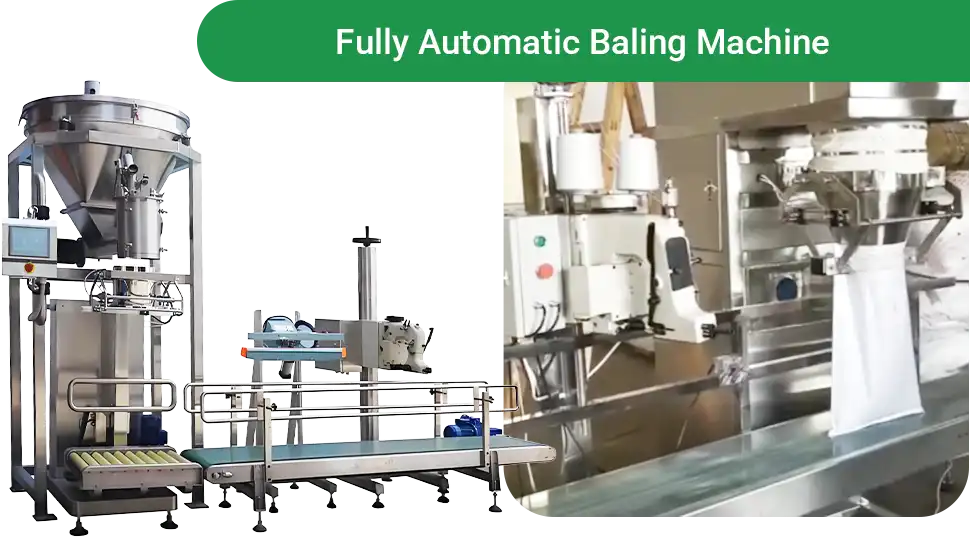

6.Packaging and Storage

Once dried, the pellets can be packed in bulk or small portions, depending on your product strategy. Use moisture-resistant bags to keep the quality stable.

Smaller batches help maintain freshness, manage shelf life, and protect your brand's reputation.

These steps make up the basic process of producing pellet feed for pet rats. To keep everything running efficiently, it's essential to have the right equipment setup.

Kawise Machinery: Helping You Build a Better Pellet Line

Kawise Machinery has nearly 30 years of experience in feed pellet machine manufacturing. Our equipment has been shipped to the UK, Australia, Southeast Asia, South Africa, and beyond.

We don't just sell pellet machines. We build custom production lines tailored for pet rat feed.

Our engineers and technicians can design the right setup for your raw materials, production goals, and process needs. We also provide full support with installation, training, and after-sales service-so your line runs smoothly from day one.

If you're planning to enter the pet rat pellet market, we're ready to support you with a reliable solution!