You're scrolling online and spot someone selling a used pellet machine. The seller claims it's "in perfect condition, 90% new, and priced low." Sounds tempting, right? Do you jump in and buy it without a second thought? Or do you pause, wondering if this could be a risky purchase?

Let's be honest. On the surface, it looks like a great deal. But is it a golden opportunity or a potential headache?

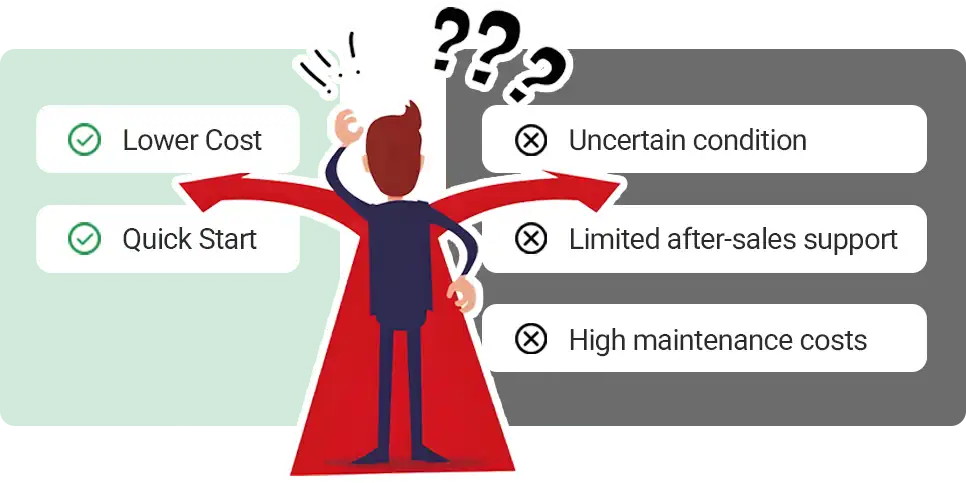

Pros and Cons of a Second-Hand Pellet Machine

For first-time buyers or those on a tight budget looking to kickstart a project, a used pellet machine can seem appealing. Here's why:

- Lower Cost: Used pellet mills usually cost less than new ones, making them easier on the wallet - especially for individuals or small startups.

- Quick Start: Buying locally means no long shipping delays. You can get the machine and start your project almost immediately.

But here's something to think about: why would someone want to sell their pellet machine in the first place?

One reason could be that they're upgrading to a larger model because the current one no longer meets their production needs. Another possibility is that the machine has started having problems, such as lower performance or frequent breakdowns, so the owner decides to replace it.

That's why buying a used pellet machine comes with some risks you can't ignore:

- Uncertain condition: Photos and videos don't always tell the full story. Many problems only appear when the machine is actually running. If you only notice them after buying, it may already be too late.

- Limited after-sales support: Most used pellet machines are no longer covered by the original manufacturer. If key parts like the roller or die break, it can be hard to find matching replacements. Without the right parts, the machine can't run properly, and repairs become much more difficult.

- High maintenance costs: Every pellet machine has a limited lifespan. With second-hand equipment, it's hard to know how long it has been used or how well it was maintained. If issues come up, you might find yourself repairing it often and spending more than planned.

Used vs New Pellet Machines: Which Is Worth It?

At first glance, a used pellet mill seems like the cheaper option. But when you look at long-term costs, it might not be the better deal. Here's a cost comparison based on a reasonable set of assumptions.

| Item | New Pellet Machine | Used Pellet Machine |

| Purchase Cost | $600 | $300 |

| Shipping Cost | $200 | $20 |

| Initial Investment | $800 | $320 |

| Annual Maintenance Cost | $180 | $380 |

| Expected Lifespan | 10 years | 5 years |

| Resale Value | $100 | $10 |

| Total Lifetime Cost | $2,300 | $2,210 |

| Average Annual Cost | $250/year | $442/year |

(Note: This calculation is based on the KD-210 feed pellet machine (250–400 kg/h) as an example.)

The data shows that new machines tend to be more cost-effective in the long run. Many users have seen this for themselves through real-world use:

In August 2021, a Texas farmer reached out to us through our website. He wanted a flat-die biomass pellet machine to process agricultural byproducts. Based on his raw materials, we recommended the KB-300 model (250–350 kg/h output) for $4,050, including the machine and shipping. He thought the price was a bit high, so he went with a cheaper used machine instead.

But within two months, trouble started. The used machine kept clogging. The die cracked. Repair costs piled up, and some parts were impossible to replace. Production stalled. By late October, he bought the KB-300 we suggested.

Once in use, it ran smoothly, produced solid pellets, and worked far more efficiently. He admitted, "I should've gone with the new machine from the start. It's less hassle."

That said, not every new machine guarantees great results. Picking a reliable manufacturer with solid after-sales support is what really matters.

Kawise: A Hassle-Free, Money-Saving Way to Buy a Pellet Machine

Kawise, a professional pellet machine manufacturer from China, has been in the industry for over 20 years. With deep expertise and technical know-how, our machines are exported to countries like Bangladesh, India, South Africa, Vietnam, Zambia, and the U.S. Our quality and service consistently earn high praise.

We don't just sell pellet machines. We also offer complete production line design tailored to your needs. Our own factory and skilled engineering team provide on-site installation, technical guidance, and operator training. All our machines come at factory-direct prices with a 12-month after-sales service for your peace of mind.

Buying a pellet machine isn't a one-time purchase. It's a long-term partnership with a manufacturer. We're confident we can be a reliable partner on your production journey. Contact us today to get a customized pellet machine solution that fits your needs!