The self-suction crusher uses airflow feeding for efficient crushing. It is mainly used for corn, wheat, soybeans, rice, and other grains, as well as feed materials.

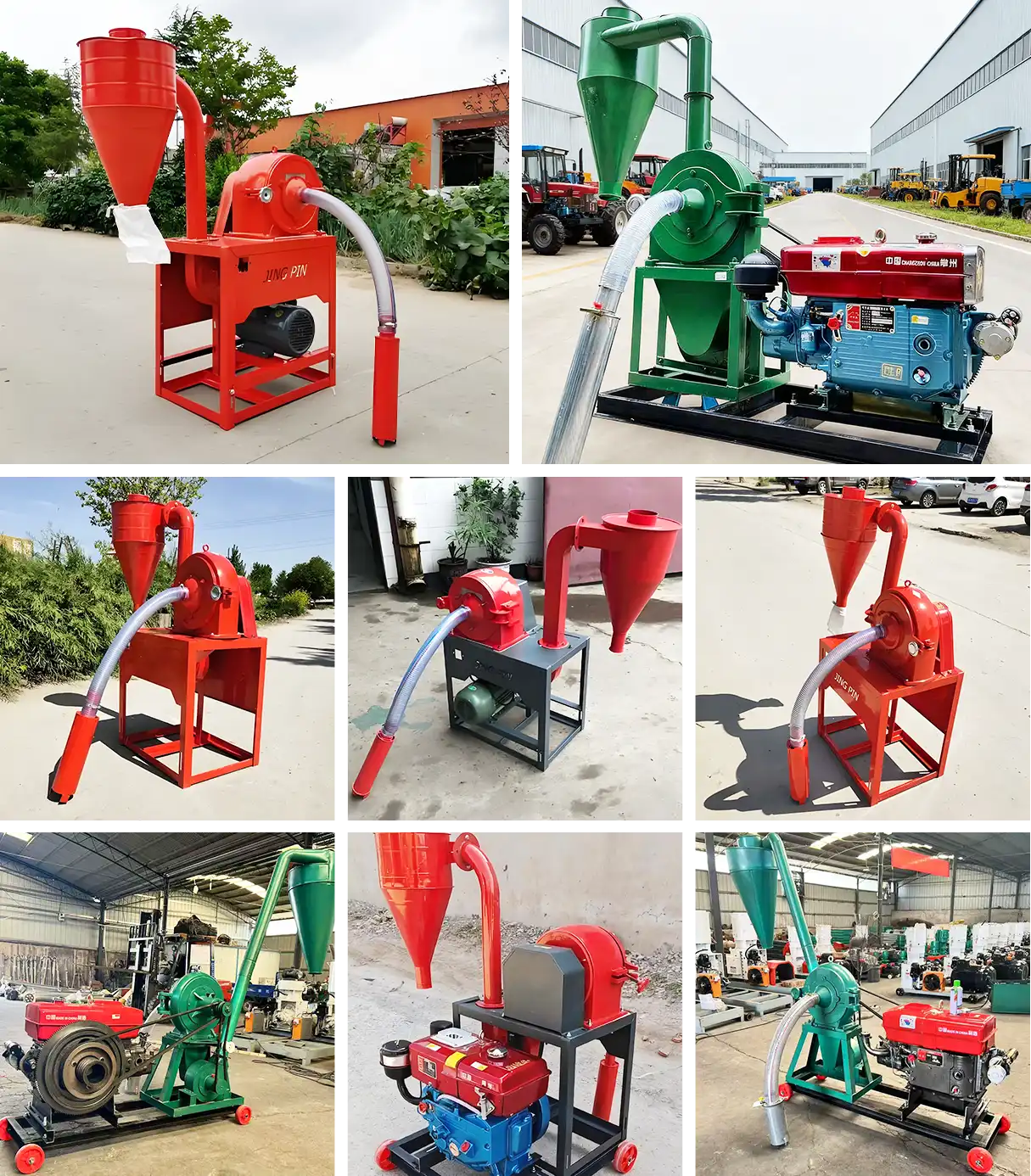

With high automation, low energy use, and compact design, it is ideal for farms, livestock owners, small feed mills, and grain processing sites.

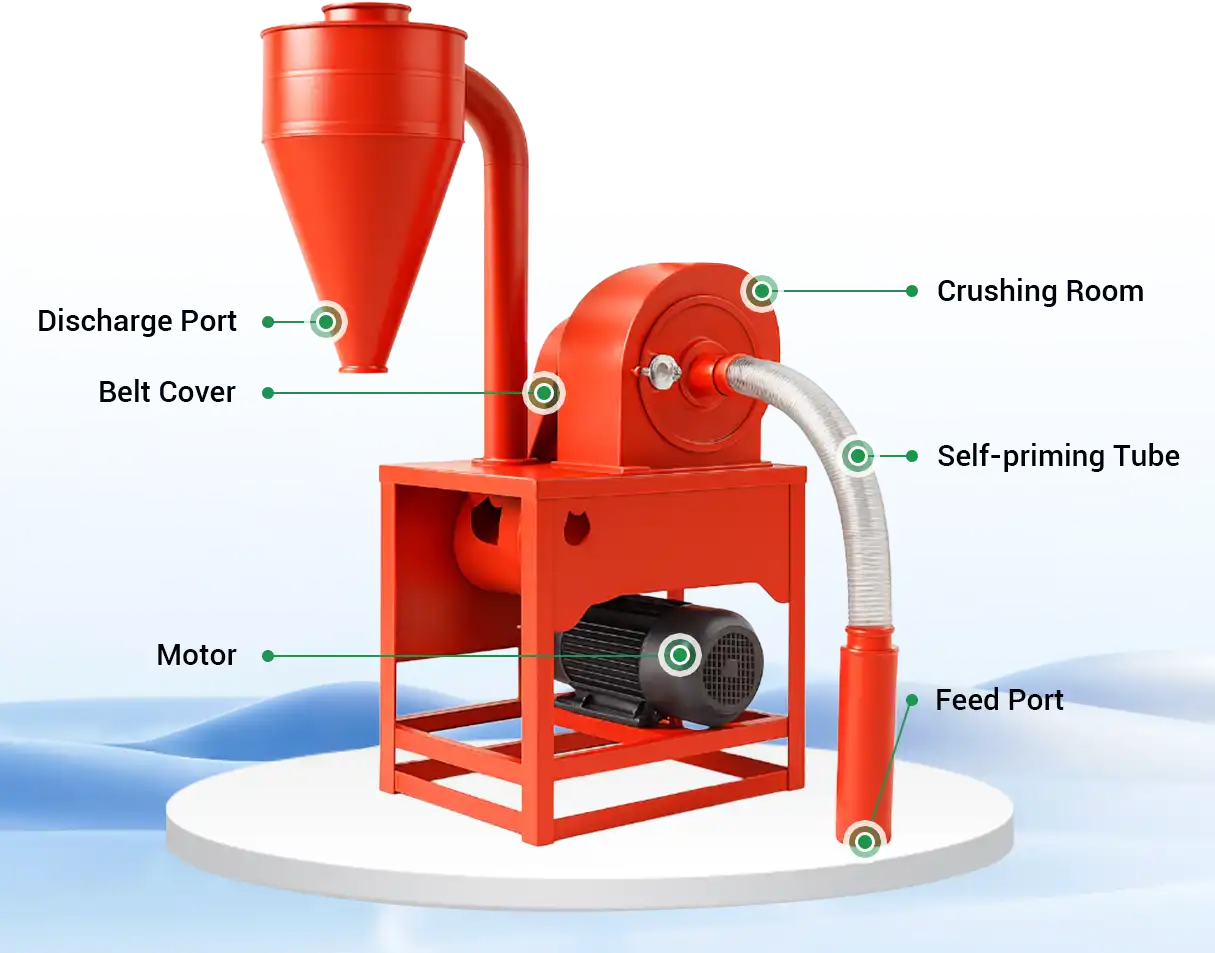

Structure and Working Principle

The self-suction crusher mainly consists of a power system, fan, feeding pipe, crushing chamber, hammers, screen, and discharge outlet.

The self suction crusher uses fan suction to draw material into the chamber, where high speed hammers crush it by impact and shear.

Airflow carries particles through the screen; qualified ones are discharged, while larger pieces are recirculated until fully crushed.

One Machine for Many Materials

Why Our Products Stand Out

From design to performance, every detail is made to deliver reliable results for your daily work.

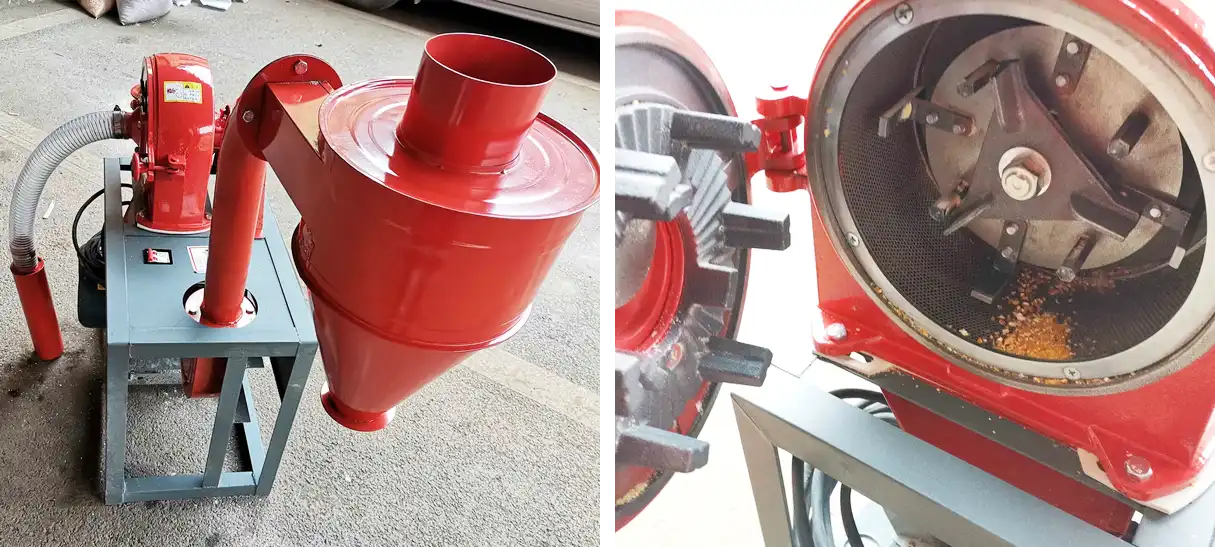

Replaceable Screens

Comes with 0.6–10 mm screens for different grains like corn, wheat, and soybeans. Easy to switch for feed use or pellet preparation, with adjustable particle size for flexible needs.

Durable Build

Made with thick steel and wear resistant hammers, the machine runs stably under heavy use, reduces maintenance, and lasts longer.

Compact Design

Small footprint, easy to install, move, and transport, saving space and cost.

Improved Airflow

Upgraded fans ensure smooth feeding, less clogging, faster discharge, and reduced dust for better efficiency and a cleaner working environment.

Product Specifications

| Model | Power (kw) | Capacity (kg/h) |

| 21 | 3 | 300–800 |

| 23 | 4 | 500–1000 |

| 280 | 3 | 300–800 |

| 300 | 4 | 500–1000 |

| 300 | 7.5 | 1000–2000 |

| 360 | 11 | 1000–3000 |

* Optional diesel engine for use without electricity.