Standard pellet mills struggle to meet outdoor users' needs due to power and location limitations.

To address this issue, we recommend the PTO pellet mill. It is powered directly by tractors or other agricultural machinery equipped with a PTO shaft. You can operate it flexibly anywhere. A smart choice if you already have the equipment.

Key Advantages of the PTO Pellet Machine

- Flexible power source: You have many power options that do not depend on a fixed electricity supply. This makes it suitable for different working conditions.

- Low cost, high return: It requires no extra motor or engine, reducing investment and increasing ROI.

- Easy to use: Simple to install, operate, and maintain. Easy to learn, even for beginners.

- Versatile application: Capable of processing corn stalks, wheat straw, manure, and more. Perfect for producing feed or organic fertilizer, meeting diverse production needs.

- Eco-friendly: Transforms waste materials into valuable resources, reducing environmental pollution and promoting sustainable development.

Working Principle of the PTO Pellet Machine

By using a drive shaft, the PTO pellet mill is connected to power machinery (such as tractors or other agricultural equipment) equipped with a PTO interface. The universal joint adjusts the angle, allowing smooth power transmission to drive the pellet mill.

Pelletizing Process of the PTO Pellet Machine

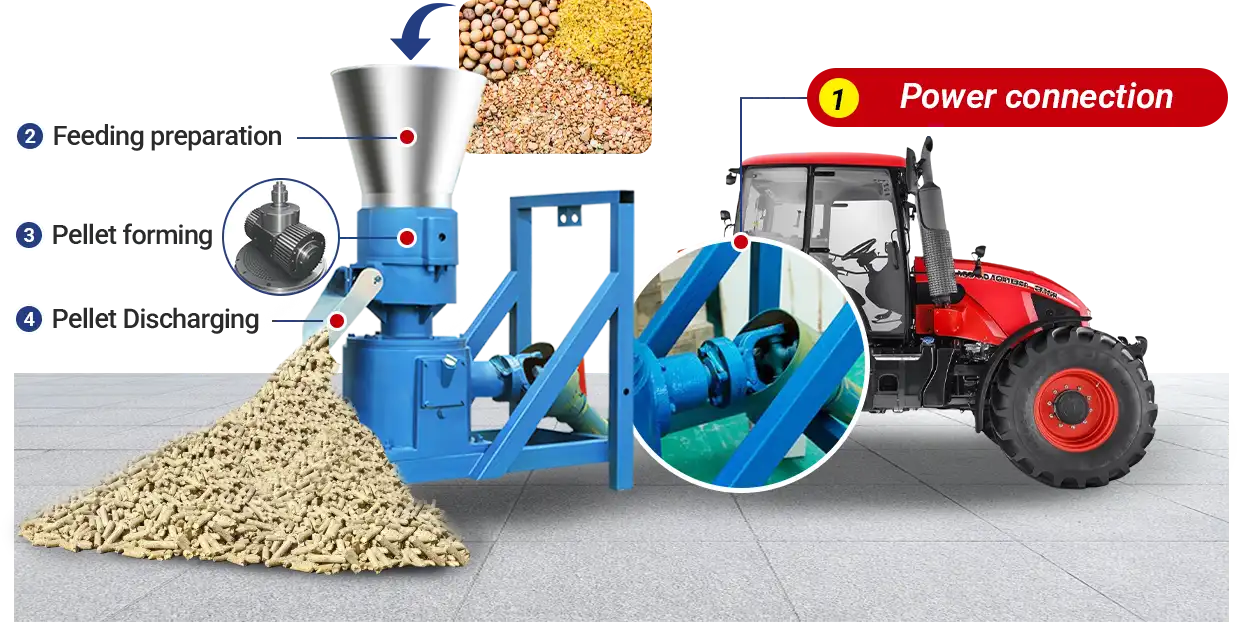

Understand the pelletizing process of the PTO pellet mill in just five simple steps.

- Power connection: Connect the drive shaft to the tractor's PTO output port and the pellet mill's input port. Adjust the angle using the universal joint to ensure smooth power transmission.

- Feeding preparation: Evenly feed the mixed raw materials into the hopper.

- Pellet forming: The tractor drives the rollers and die to rotate, compressing the materials under high temperature and pressure. The raw materials are extruded through the die holes to form pellets.

- Cutting and discharge: The pellets are cut to the desired length by the cutter and discharged through the outlet.

- Cooling and storage: The pellets are naturally cooled or processed by a cooling device, then packaged or stored.

KAWISE PTO Pellet Machine Models and Capacities

Below are the available models and their capacities to suit different production needs.

| Model | Power (hp) | Capacity (kg/h) | Roller | Die Hole (mm) |

| KD-150P | ≥8 | 80-150 | 2 | 2.5-8 |

| KD-160P | ≥8 | 130-200 | 3 | 2.5-8 |

| KD-210P | ≥15 | 200-300 | 2 or 3 | 2.5-8 |

| KD-230P | ≥18 | 250-400 | 3 | 2.5-8 |

| KD-260P | ≥22 | 300-500 | 3 or 4 | 2.5-8 |

| KD-300P | ≥35 | 500-700 | 4 | 2.5-8 |

Tips for Using the PTO Pellet Machine

- Ensure that the tractor's power output is within the required range of the pellet mill.

- Before connecting, check whether the universal joint of the drive shaft is flexible and free from damage. Make sure the connection is secure to prevent disconnection during operation, which could cause injury.

- Different raw materials require different moisture levels. Make sure the material moisture content is within the appropriate range (typically 10%–15%).

- During operation, never put hands or any body parts into the feed inlet or discharge outlet.

- If there is a blockage, turn off the tractor PTO output. Wait until the machine stops completely before cleaning or doing maintenance.

More Support: After purchase, we provide a detailed user manual and expert support to help you quickly master operating skills and ensure efficient machine performance. enquire now

Why Choose KAWISE

- Advanced Technology: Core components are made of high-strength alloy steel and wear-resistant materials. Precision machining and heat treatment ensure durability and reliability under high pressure and heavy load conditions.

- Efficient Pelletizing: KAWISE PTO pellet mills produce smooth, high-density pellets with stable performance, ensuring continuous production. They help reduce energy consumption and labor costs effectively.

- Competitive Pricing: Factory-direct supply offers more competitive prices, saving you procurement costs.

- Full Range of Models: We offer different models and can customize a solution to fit your production needs.

- Comprehensive Service: From model selection, installation, and operation training to after-sales support, we provide everything you need.

At KAWISE, we are committed to providing each customer with efficient and reliable PTO pellet mill solutions. Feel free to contact us anytime - we'll recommend the most suitable model tailored to your needs and offer you a personalized quote!