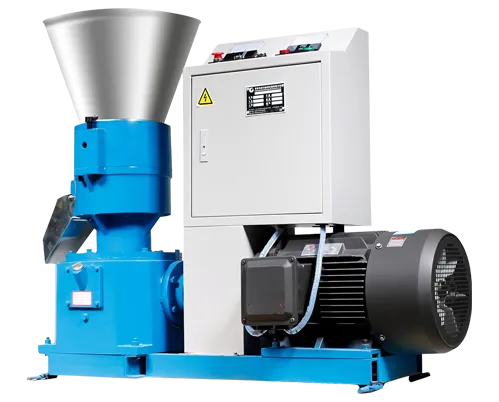

Our organic pellet machine is ideal for home farms, small to medium-sized farms, and organic fertilizer plants. It converts organic waste (like manure, crop residues, and gardening waste) into high-quality fertilizer pellets. With a versatile output range, it's perfect for small-scale production. The particle size is adjustable to meet different crop needs.

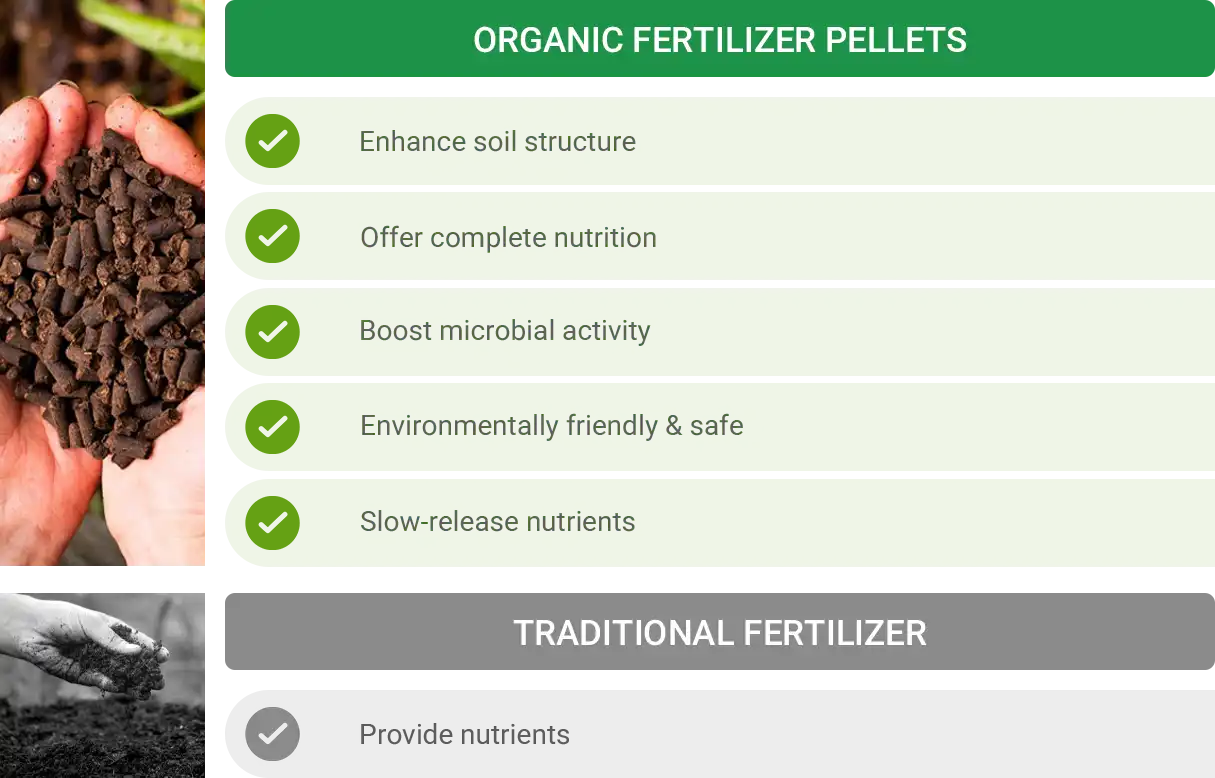

Benefits of Organic Fertilizer Pellets

Organic fertilizer pellets can improve soil fertility, promote healthy crop growth, and offer an eco-friendly, efficient fertilizing solution:

- Easy to store, transport, and apply.

- Provide steady, long-lasting nutrients.

- Improve soil aeration and water retention.

- No odor after processing and safe for the environment.

- Release nutrients slowly to boost yield and quality.

- Turn agricultural waste into valuable fertilizer.

Organic fertilizer pellets are better for the environment and help reduce pollution. It provide a slow, long-term release, so you don't have to fertilize frequently. Choose organic fertilizer pellets for a sustainable, greener future for your farmland and gardens!

Applicable Raw Materials

| Type | Raw Material |

| Livestock and poultry manure | Pig manure, cow dung, chicken manure, sheep manure, etc. |

| Crop straw | Such as corn straw, rice straw, wheat straw, bagasse |

| Forestry waste | leaves, twigs, sawdust, etc |

| Municipal garbage | Such as kitchen waste, greening waste, etc. |

| Food processing waste | Fruit and vegetable peel, coffee grounds, distiller's grains |

| Algal matter | Seaweed, kelp, etc., with high organic matter content |

| Garden waste | Lawn clippings, garden plant stumps, flowers |

These materials are rich in organic matter. You can turn these raw materials into pellets with just a few steps with organic fertilizer pellet machine. The pellet shapes are ideal for processing, transport, and use.

Easy Operation Steps

- Remove impurities from organic waste like manure and crop residues.

- Crush materials to below 5mm for smooth processing.

- Add minerals or nutrients as needed and mix well.

- Feed materials steadily into the pellet machine.

- Collect the pellets and allow them to cool to room temperature.

- Store pellets in a dry, ventilated place to keep them moisture-free.

- Follow these steps to easily produce high-quality organic fertilizer pellets that improve soil and boost crops.

By following these steps, you'll produce high-quality organic fertilizer pellets. It can help improve soil fertility and boost your crop growth.

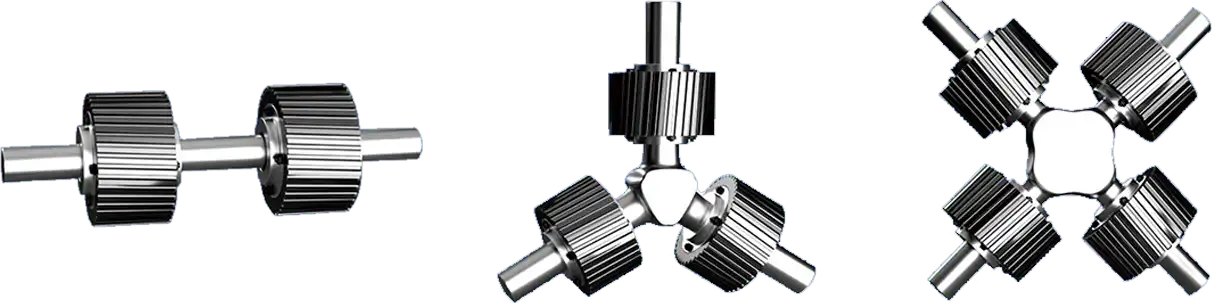

Equipment Specifications

| Model | Capacity (kg/h) | Roller | Application |

| 150 | 80-150 | 2 | Small farms, personal use |

| 160 | 130-200 | 3 | Small farms |

| 210 | 200-300 | 2/3 | Small to medium farms |

| 230 | 250-400 | 3 | Small to medium farms |

| 260 | 300-500 | 3/4 | Medium farms |

| 300 | 500-700 | 4 | Medium farms |

| 400 | 900-1200 | 4 | organic fertilizer producers |

Mold sizes available: 2.5 / 3 / 4 / 5 / 6 / 8mm

Power range: 4.5 - 37Kw, energy-efficient

Material: High-strength alloy steel (chromium-manganese), resistant to heat, corrosion, and wear.

Why Choose Our Organic Fertilizer Pellet Mill?

- Simple design & easy to operate: Easy to take apart for cleaning and maintenance, saving time and labor costs.

- Compact and portable: Saves space and includes wheels for easy movement.

- Durable & reliable: Uses advanced compression technology and custom molds to keep pellets firm and uniform, even with heavy use.

- Handles various raw materials: Processes different organic waste efficiently, maximizing recycling.

- Eco-friendly: Emits no gas emissions and complies with environmental standards.

- Full after-sales support: Includes installation, setup, and technical guidance to help you start quickly.

Usage Tips

- Pre-crush materials: Crush raw materials evenly for smooth feeding and higher pellet quality.

- Moisture control: Maintain moisture levels between 15% and 20%. Too wet makes pelletizing hard; too dry weakens pellets. (Tip: Proper moisture allows the material to clump together without sticking to your hands.)

- Mix raw materials: Combine manure, straw, crop residues, etc., for balanced nutrition. Avoid using a single material. Add natural binders like water or starch if needed.

- Add natural binders: Use molasses or beet pulp to strengthen pellets and reduce breakage.

- Control temperature: Avoid production during hot midday hours. Work in cooler mornings or evenings to prevent pellet deformation.

Kawise organic fertilizer pellet machine -- your complete solution for efficient, reliable pellet production!

Contact us today for a personalized quote and technical support.