The hammer mill is a high efficiency grinding machine widely used in feed processing.

It can quickly crush corn, soybean, rice, wheat and other raw materials, producing uniform particles suitable for feed and biomass production.

Structure & Working Principle

The hammer mill mainly consists of the main body, feeding port, crushing chamber (hammers and screen), collector, and discharge port.

Material enters the chamber and is crushed by high-speed hammers, then screened into uniform particles and discharged.

With a reinforced body and wear-resistant hammers, the machine runs stably and efficiently handles corn, soybean, wheat, rice and other feed materials.

Applicable Materials

The hammer mill can be used to crush a variety of agricultural materials, including corn, wheat, soybean, sorghum, and other grains.

It is also suitable for grinding plant stems, leaves, and other biomass materials.

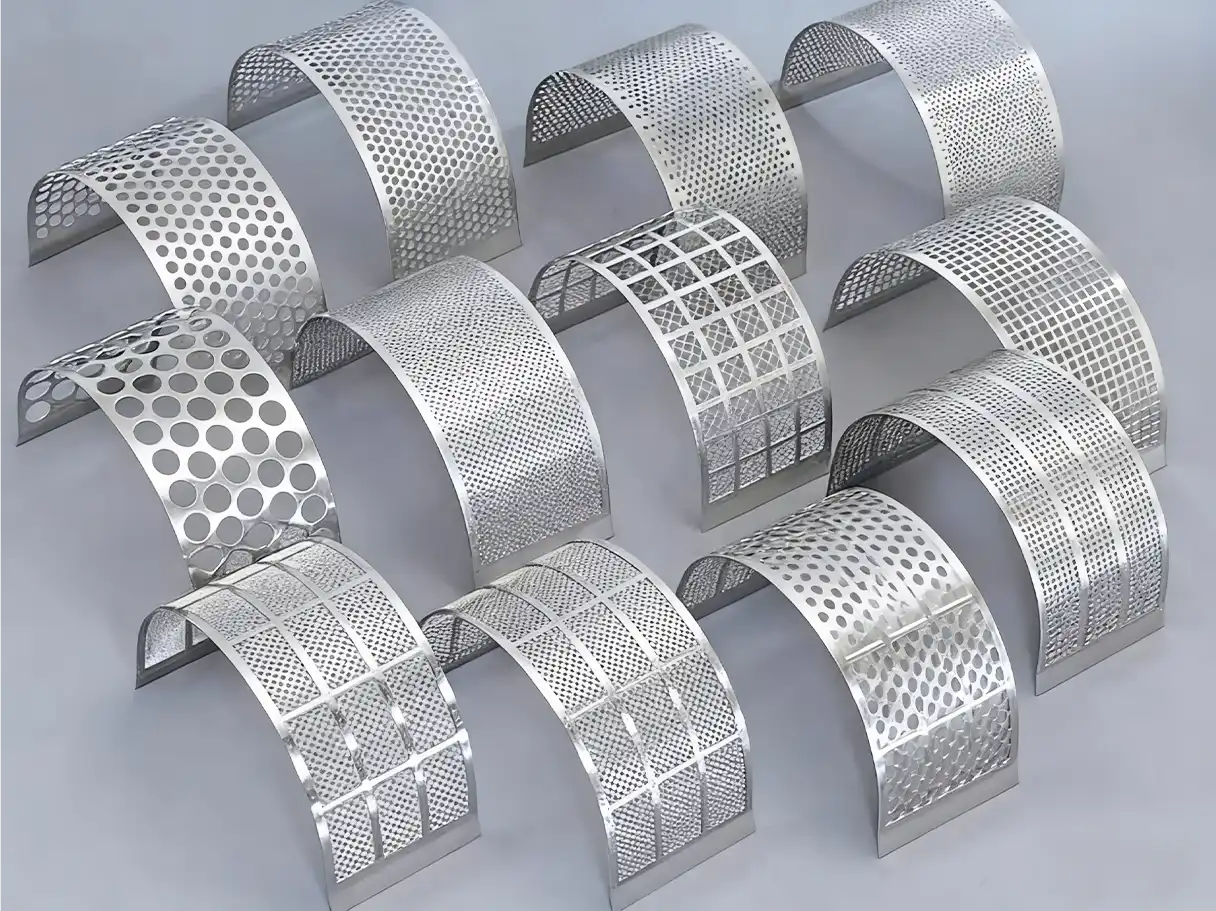

Adjustable Output Size

The hammer mill supports multiple screen options, allowing precise control of final particle size.

Depending on production needs, we offer screens in 1 / 2 / 3 / 5 / 6 / 8 / 10 / 15 / 20 / 25 / 30 mm sizes, suitable for both coarse and fine grinding.

For multiple particle sizes, it is recommended to order the required screens together with the machine to save on later shipping and waiting costs.

Product Details

- Durable hammers for faster, efficient grinding

- Wide feed port for smooth, easy loading

- Strong body structure built to last

- Dust-proof discharge for a cleaner workspace

- Quality finish with lasting rust protection

- Easy-to-move design with reliable nylon wheels

Product Parameters

| Model | Capacity (kg/h) | Host power (kw) |

| 350 | 200-350 | 4.5 |

| 360 | 400-600 | 4.5 |

| 400 | 500-700 | 7.5 |

| 420 | 800-1000 | 7.5 |

| 500 | 1000-1500 | 15 |

| 600 | 1500-2000 | 22 |

| 750 | 2000-3000 | 30 |

*Additional feed inlet can be installed. Diesel configuration available on request.

Operation Notes

- Check that rotor and hammers are securely fixed before use.

- Keep metal, stones, and other hard objects out of the machine.

- Wet materials may block the machine and wear parts faster. Keep moisture under control.